For decades, agricultural automation relied on hard mechanical grippers—metal claws or rigid plastic jaws—that excelled at lifting heavy, durable goods but failed miserably with delicate produce. As global demand for fresh fruits and vegetables surged (the OECD projects a 25% increase in produce consumption by 2030), farmers needed a tool that could balance speed with care. The breakthrough came from advances in flexible polymer science: by the mid-2010s, engineers developed the soft gripper, a device that uses elastic, skin-like materials to mimic human dexterity. What began as a niche solution has now become essential for modern farms—and not just for its gentleness. Below are five compelling reasons to adopt this technology.

1. Preserving Produce Integrity: The “Gentle Touch” That Boosts Profit

The soft gripper’s most obvious strength is its ability to protect fragile crops from damage—a make-or-break factor for high-value produce. Unlike hard grippers that press on narrow points (often causing bruising or splitting), soft designs use silicone or thermoplastic elastomers to spread pressure across the produce’s surface. Take a Dutch raspberry farm near Utrecht: before switching to a soft gripper, 18% of its raspberries were discarded due to claw marks or crushed hulls. After adoption, that rate plummeted to 2%. The gripper’s fingers—flexible enough to wrap around a raspberry without piercing its skin—apply just 2-4 psi of pressure, roughly the same as a human hand holding a ripe peach. For farmers selling to premium markets (like organic grocery chains in Berlin or Paris), this quality retention directly translates to higher prices and repeat customers.

2. Adaptability Across Crops: No More Tool Swaps

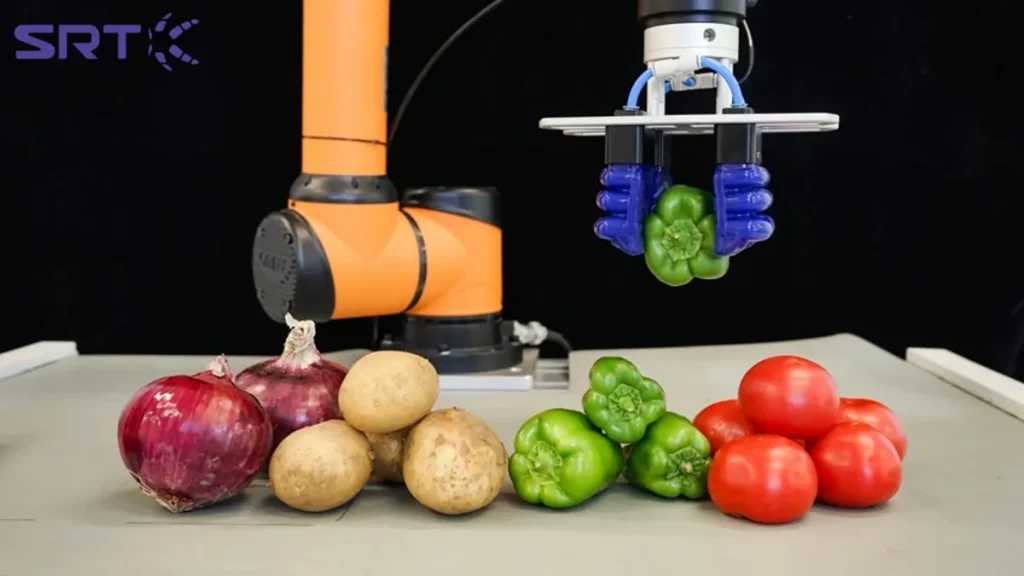

Traditional automated systems force farmers to halt operations when switching between crops. A hard gripper calibrated for apples, for example, can’t handle asparagus or blueberries without 30+ minutes of adjustments. The soft gripper eliminates this downtime with its shape-shifting design. Its flexible fingers naturally conform to irregular sizes and textures—from the bumpy skin of kiwis to the long, thin stalks of celery—without manual reconfiguration. A family-owned farm in California’s Central Valley, which grows both strawberries and bell peppers, saw a 40% productivity boost after adopting the technology. Previously, workers spent 15 minutes swapping gripper heads between harvests; now, the same soft gripper moves seamlessly from berries to peppers, cutting idle time in half. This versatility is a game-changer for small farms that grow 3+ crops annually, as it eliminates the need to buy multiple specialized tools.

3. Cutting Post-Harvest Waste: A Win for Sustainability

Food waste is a crisis in the West—with the EU estimating that 28% of fruits and vegetables are lost after harvest, mostly due to handling damage. The soft gripper tackles this by keeping produce intact, extending shelf life and reducing landfill waste. A study by Italy’s University of Bologna found that tomatoes handled by a soft gripper stayed fresh for 8 days longer than those damaged by hard grippers. For a Spanish citrus farm in Valencia, this meant 12% less oranges discarded before reaching supermarkets. Beyond reducing waste, the technology also lowers carbon footprints: less spoiled produce means fewer resources spent on replanting, fertilizing, and transporting replacements. For farms seeking EU Green Deal certifications, the soft gripper has become a key tool to meet sustainability targets—and appeal to eco-conscious shoppers.

4. Lower Maintenance Costs: Durability That Saves Money

Hard grippers are prone to wear and tear: their metal parts rust, plastic jaws crack, and calibration drift requires frequent repairs. A 2023 report by the American Society of Agricultural and Biological Engineers (ASABE) found that farms spend an average of $1,200 annually on maintaining hard grippers. The soft gripper, by contrast, uses durable, corrosion-resistant materials that withstand outdoor conditions (like humidity or pesticide exposure) with minimal upkeep. A cherry farm in Michigan’s Traverse City reported that its soft gripper operated for 18 months without repairs—compared to 6 months for its previous hard gripper. The savings add up: for mid-sized farms, switching to a soft gripper can cut annual maintenance costs by 50% or more.

5. Enhancing Worker Safety: Reducing On-Site Risks

Hard grippers pose safety hazards: their rigid parts can jam, snap, or cause blunt-force injuries if workers get too close. In the U.S., the Occupational Safety and Health Administration (OSHA) records hundreds of farm injuries annually linked to mechanical grippers. The soft gripper’s flexible design minimizes these risks: its elastic fingers don’t shatter or create sharp edges, and their gentle pressure reduces the chance of accidental crushing if a worker’s hand gets near. A citrus farm in Florida’s Orlando area saw a 75% drop in gripper-related injuries after adopting the technology. Workers also report less stress, as they no longer need to monitor hard grippers for jams or malfunctions—freeing them to focus on more skilled tasks like quality checking.

Conclusion

The soft gripper is more than a “gentle alternative” to hard tools—it’s a multi-faceted solution that addresses farmers’ biggest pain points: quality loss, inefficiency, waste, costs, and safety. From Dutch raspberry farms to Florida citrus groves, it’s proving its value by boosting profits, cutting waste, and making workplaces safer. As agricultural automation evolves to meet consumer demands for fresh, sustainable produce, the soft gripper isn’t just an option—it’s a necessity. For any farm looking to thrive in the modern market, the choice is clear: prioritize care, versatility, and practicality—choose the soft gripper.