If you’re hearing an unexpected knocking sound on the right side of your 2001 Bombardier DS 650, particularly near the stator area, you’re not alone. This mechanical issue is common among DS 650 owners as the machines age. The noise can signal a range of problems—from simple wear and tear to complex internal failures. Understanding what’s happening beneath the plastics is crucial before jumping into repairs or replacements – 2001 ds 650 knocking on right side stator.

This article will guide you through the likely causes, mechanical background, diagnostic methods, and repair options related to right-side knocking around the stator region of the DS 650, offering insight from both an engineering and rider’s perspective. Whether you’re an experienced mechanic or a DIY enthusiast, this comprehensive resource is designed to equip you with the knowledge to accurately assess and resolve the issue without guesswork.

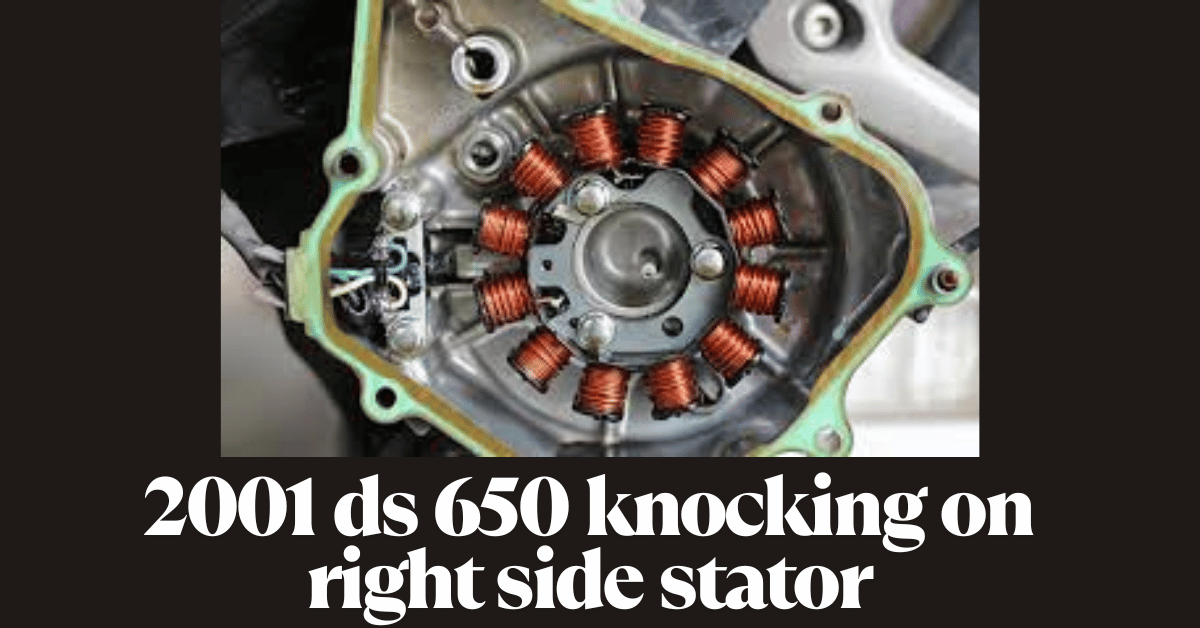

Understanding the DS 650 Engine and the Role of the Stator

To properly assess any knocking near the stator, we need to understand the engine layout of the 2001 DS 650. This quad is equipped with a 653cc Rotax single-cylinder four-stroke engine, liquid-cooled and known for its power and durability. It’s paired with a five-speed manual transmission and chain final drive.

The stator is located on the right-hand side of the engine, housed within the stator cover. It is responsible for generating electrical power for the quad’s systems by converting mechanical energy into AC electricity. While it doesn’t move itself, it’s directly influenced by the rotating flywheel, which is bolted to the crankshaft and spins within proximity – 2001 ds 650 knocking on right side stator.

Any knocking sound from this region can stem from interference between these components, bearing wear, misaligned shafts, or more complex crankcase issues.

Common Causes of Right-Side Knocking in the 2001 DS 650

The causes of knocking near the stator area fall into several categories. Below is a breakdown of the most frequent issues:

| Cause | Description |

|---|---|

| Worn or damaged stator bearing | Can result in flywheel misalignment, causing mechanical contact and rhythmic knocking sounds |

| Loose flywheel or rotor | A loose bolt or improperly seated flywheel will cause wobble and knock |

| Crankshaft end play | Excessive lateral movement can cause the flywheel to tap or rub inside the stator housing |

| Damaged stator windings | If the stator is compromised, it can create friction or noise when interacting with other components |

| Broken or loose starter gear | Inside the same side case, the starter gear can rattle if damaged or disconnected |

| Transmission gear contact | Occasionally mistaken as stator noise, it may originate from adjacent gear wear or clutch issues |

| Foreign object contamination | Debris inside the housing can cause intermittent knocks and scoring of components |

Diagnosing the Knocking Sound: A Step-by-Step Inspection Protocol

To properly determine the source of the knock, a systematic diagnostic is required. Below is a procedural guide for inspection:

1. Initial Acoustic Diagnosis

- Use a mechanic’s stethoscope or a screwdriver to localize the sound.

- Run the engine at idle and various RPMs.

- Confirm that the knocking is consistent and emanating from the right side, near the stator.

2. Oil Condition Inspection

- Drain the oil and check for metallic particles, which may indicate internal friction or component breakage.

- Discoloration may suggest overheating or contaminant ingress.

3. Remove the Right-Side Engine Cover

- Carefully remove the stator cover (note that oil may drain—prepare accordingly).

- Visually inspect the stator, flywheel, and starter gear for signs of impact, looseness, or scoring.

4. Check Flywheel Tightness and Alignment

- Inspect the flywheel bolt torque.

- Check for side-to-side play.

- Spin manually to ensure smooth rotation without grinding or friction points.

5. Inspect Crankshaft End Play

- Using a dial gauge, measure axial play.

- Excessive movement suggests internal wear or a failed thrust washer.

6. Test Electrical Continuity (Secondary Check)

- Verify the stator is functioning correctly.

- Although not related to noise, electrical failure can indicate deeper component stress or damage.

Differentiating Knocking from Ticking or Rattling

Not all engine noises are created equal. Understanding the character of the noise can narrow the diagnostic field.

| Noise Type | Potential Cause | Typical Tone |

|---|---|---|

| Knocking | Mechanical collision or bearing play | Deep, rhythmic |

| Ticking | Valve clearance or timing issues | Light, repetitive |

| Rattling | Loose component or gear backlash | Irregular, sharp |

Knocking is usually more concerning and directly connected to structural movement or interference.

Detailed Examination of Key Components

1. Stator and Mounting Points

- Ensure the stator is tightly mounted with no broken bolts or insulation damage.

- If it’s rubbing against the flywheel, replacement is likely required.

2. Flywheel Rotor

- Check for scoring, warping, or cracks.

- A bent rotor will not maintain concentric rotation, creating an oscillating knock.

3. Starter Gear and One-Way Clutch

- Located in proximity to the stator, a failing one-way clutch can mimic knocking.

- Try rotating the starter gear by hand—look for smooth resistance in one direction and locking in the other.

4. Crankshaft and Bearings

- If the crankshaft feels loose, the problem may extend deeper than just the stator assembly.

- This level of wear requires full engine disassembly and inspection.

Solutions and Repairs

Once the specific fault has been identified, the next step is repair. Below are repair pathways based on the identified issue:

| Issue Found | Recommended Action |

|---|---|

| Loose flywheel | Retorque to spec (check service manual); apply threadlocker |

| Worn stator bearing | Replace bearing and inspect for collateral damage |

| Faulty crankshaft end play | Engine teardown; inspect main bearings and thrust washers |

| Damaged stator | Replace with OEM or high-quality aftermarket component |

| Failed starter gear | Replace one-way bearing and gear system |

| Debris inside stator housing | Clean housing thoroughly, inspect for residual damage |

Preventive Maintenance Recommendations

To avoid recurrence or further damage, consider implementing the following practices:

- Regular Oil Changes: Contaminated oil can accelerate wear in moving engine components.

- Engine Warm-Up: Cold starts without adequate warm-up can cause uneven expansion and metal contact.

- Torque Inspections: Periodically check flywheel and stator bolts for proper torque.

- Use Quality Parts: Aftermarket parts may not maintain factory tolerances—stick with trusted sources.

- Listen to Your Machine: Any change in engine tone or feel should prompt inspection.

When to Seek Professional Help

While many repairs are DIY-capable, persistent or unclear knocking sounds warrant professional inspection, especially when they suggest deeper engine issues. If the crankshaft bearings or gear lash tolerances are out of spec, riding the machine further could cause catastrophic failure.

Professional shops can also perform magnetic particle inspections, endoscopy of the crankcase, and precision balancing of the rotor and shaft—tasks typically beyond the scope of a home garage.

The Broader Picture: Age and Fatigue in Older ATVs

The 2001 DS 650, while a solid and powerful machine, is over two decades old. Components like stator windings, seals, gears, and bearings naturally degrade over time. If your quad is seeing regular use without a recent rebuild, these issues are more likely to appear.

Replacing a stator or rotor might solve today’s knocking, but consider the potential need for a comprehensive refresh of the engine. Modern rebuild kits, gasket sets, and electrical harnesses are more available now than ever—making it a worthwhile investment for those who wish to preserve and ride the machine long-term.

Troubleshooting Table Summary

| Symptom | Most Likely Cause | Solution |

|---|---|---|

| Rhythmic knocking from right side | Loose flywheel or rotor | Retorque and inspect shaft |

| Knocking and no electrical output | Failed stator | Replace stator |

| Knock increases with RPM | Crankshaft end play | Inspect bearings and thrust washers |

| Knock when starting only | Starter gear play or failure | Replace one-way clutch and gear |

| Knock with vibration | Warped flywheel or crank imbalance | Replace flywheel or inspect crankshaft |

Final Thoughts: Don’t Ignore the Knock

When your 2001 DS 650 begins knocking from the stator side, it’s not just an annoyance—it’s a mechanical cry for help. Prompt diagnosis and action can save hundreds of dollars and many hours of future labor. Whether it’s as simple as a loose bolt or as involved as a crankshaft rebuild, the knock signals something real. Listen, inspect, and address it with confidence.

The DS 650 remains a powerful legacy machine, and with attentive maintenance and occasional mechanical overhauls, it can still dominate trails and dunes for years to come.

FAQs

1. What causes a knocking sound near the stator on my 2001 DS 650?

The knocking is usually caused by a loose flywheel, worn stator bearing, crankshaft end play, or a failing starter gear. It often indicates mechanical interference between rotating and stationary components near the stator.

2. Is it safe to ride my DS 650 if I hear knocking from the right side?

No. Continued riding can worsen internal damage, especially if the issue involves the crankshaft or bearings. Prompt inspection is recommended to avoid costly repairs.

3. How do I know if the stator is the actual cause of the knocking?

After removing the right engine cover, inspect for visible wear, loose bolts, flywheel play, or scoring. Rotating the flywheel manually and checking end play can help confirm the source.

4. Can I fix the knocking issue at home, or do I need a mechanic?

Many causes, like loose bolts or a worn stator, can be fixed at home with basic tools. However, if crankshaft end play or internal engine wear is involved, professional repair is advised.

5. How much does it cost to replace or repair the stator on a 2001 DS 650?

A stator replacement typically costs between $80–$200 for parts, plus labor if done professionally. If deeper engine work is required, costs may rise significantly based on the extent of the damage.