With the growing shift towards sustainable energy, solar power is recognised as a leader in the renewable energy revolution. Homeowners are realizing the potential for cleaner air and lower energy bills by going solar, but are left with an important choice on the individual piece of it: monocrystalline vs. polycrystalline solar panels. This decision makes a dramatic impact on system efficiency, lifetime costs, and total performance. Both convert sunlight into electricity, but their manufacturing techniques, efficiency rates, and economics are quite different. Knowing these differences will help you make a good investment decision that suits your unique needs and situation. This complete comparison will look at efficient and cost-effective (never mind durable) solar panels to make your selection of a solar panel manufacturer less of a gamble. From maximum power output to budget or space constraints, this consideration will help guide you through some of the technical ins and outs, as well as daily-use factors, of both panel types.

Understanding Solar Panel Types

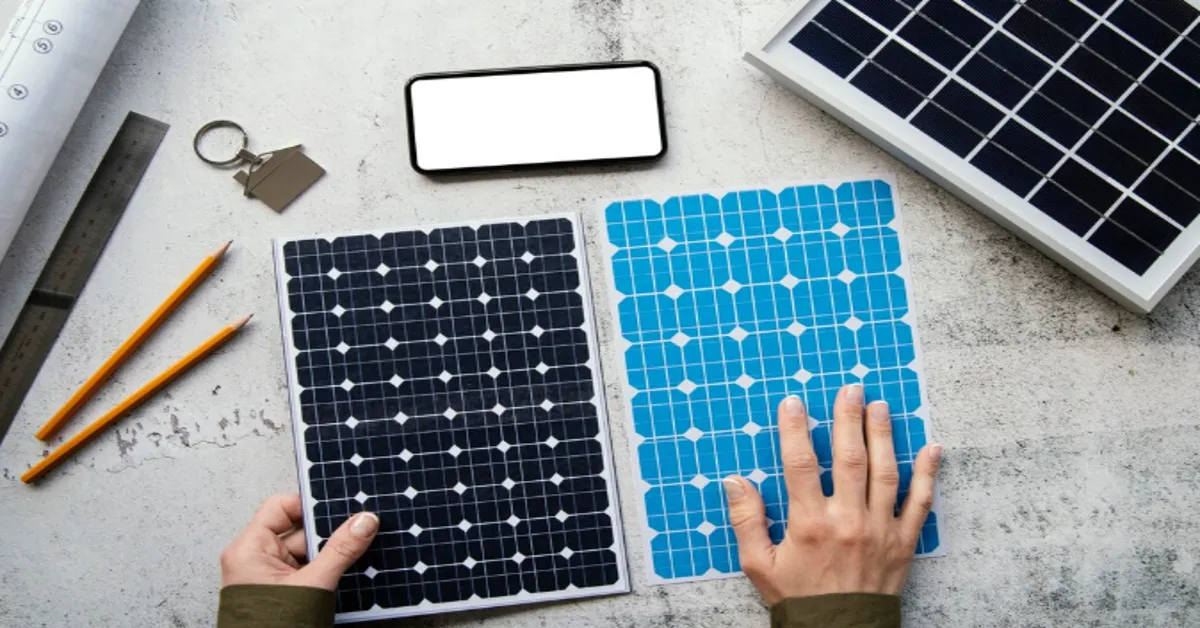

Sunlight is collected by solar panels and the photovoltaic cells which are used to convert solar energy into electric power based on a photoelectrical effect. There are two types of crystalline silicon solar cell panels – monocrystalline and polycrystalline, which are distinct in their composition and size. Monocrystalline is made from a single, pure silicon crystal that is sliced into layers that generate the cell of the panel. This care ensures each cell has that signature consistent dark look and the rounded corners of the cell. Most polycrystalline panels, meanwhile, are manufactured by melting together 36 or more fragments of silicon, producing a less uniform (and usually blue) multifaceted surface with a geometric pattern more visible to the eye. The production process for polycrystalline panels is more efficient, but the internal crystal boundaries lower the efficiency somewhat. These visual differences act as easy giveaway indicators: monocrystalline panels appear pitch black with rounder cell corners, while polycrystalline panels tend to have a bluer and patchy surface pattern with sharp-edged cells. The knowledge of these basic distinctions in constitution and flourishes derives the basis for analyzing the performance properties and uses of all these materials.

Monocrystalline Solar Panels: Features and Benefits

How Monocrystalline Panels Are Made

The Czochralski process, an advanced production technique, yields monocrystalline solar panels by forming a single silicon crystal. Here are the steps: The process starts with making the solar cell—a composition of silicon ingots that turn into slabs to get transformed into solar cells and then panels. Into the molten silicon a seed crystal is introduced which is then raised slowly rotating to extract a cylindrical ingot of pure silicon. This ingot is then sawed into thin wafers, forming the basis of monocrystalline solar cells.

Efficiency and Performance

Monocrystalline panels are known for having the highest efficiency rates, with power output of PV modules ranging from 18 percent up to 22 percent. They are more efficient because they are made from higher-purity silicon, which provides better electron flow and better absorption of sunlight. This unusually high performance is able to produce more power, by using less panel, and results in reduced installation costs in systems with limited space.

Durability and Lifespan

Performance warranty on these panels is also a standard 25-30 years, meaning that they are built to withstand and last! Their excellent heat tolerance ensures optimal efficiency, up to 0.3-0.4% lower than conventional p-type PERC, at 25°C – and due to low thermal coefficients, output dips are even lower – under 0.4% at 50°C. The single crystal nature gives natural structural stability with slower degradation rates than other panel types. Many manufacturers offer 80% plus power output after 25 years of system use.

Polycrystalline Solar Panels: Features and Benefits

Manufacturing Process

The manufacturing process is simpler in the case of polycrystalline solar panels and thus, cheaper. Raw silicon is melted and poured into square molds, then cooled so it naturally forms several crystal structures. This causes the cool blue-multi reflect effect. This technique is when light reflects off the different crystal groups, the “schiller” (light reflecting off the many sides of the crystal) being picked up by the camera. The cooled block of silicon is then sawed into wafers, which are put together to form the actual solar cells. This more crude method reduces production cost but introduces more internal crystal boundaries.

Efficiency Levels

Polycrystalline panels tend to have efficiencies in the range of 15% to 17%, so they’re slightly less efficient than monocrystalline. This constraint of efficiency is due to some extent to the multiplicity of crystal boundaries which partially hinder electron motion. But recent technological progress has closed this gap in efficiency. And, thus, modern polycrystalline panels have become more and more competitive in terms of electricity generation.

Durability Factors

These panels are also very durable, offering average warranties of 25 years, but are just a little more temperature sensitive than monocrystalline panels. The decline in overall efficiency at high temperatures is around 0.4-0.5% per Celsius degree above standard test conditions. Although they may tend to degrade a bit faster than contemporaries in the long term, correct installation and maintenance will ensure that they function with impeccable reliability during their years of use. The multicrystalline structure has even some advantage over this in indirect sunlight, making these panels very useful in places with many clouds.

Head-to-Head Comparison: Key Differences

Solar Panel Performance Metrics

Monocrystalline vs Polycrystalline panels: A direct comparison. Efficiency is one of the main differences between monocrystalline and polycrystalline. Monocrystalline vs Polycrystalline It’s simple: Monocrystalline performs better at 18-22% versus Polycrystalline at 15-17%. That means around 20-30 watts extra power per panel in the same conditions. Temperature coefficients also differ quite a lot – between 0.3-0.4% efficiency losses for monocrystalline and 0.4-0.5% efficiency drops for polycrystalline per degree above the testing conditions.

Cost Analysis

The average capital cost varies more significantly between types of panels; monocrystalline panels demand a 10-15% price premium over polycrystalline. But, this cost gap doesn’t matter that much in the long run when you take into consideration the increased energy production. For the average home, break-even time is 5-7 years with monocrystalline systems and 6-8 years with polycrystalline, in average sunlight conditions and with average energy prices.

Durability in Various Climates

Both panels have physical strength ratings (snow loads and wind pressure) that are almost the same — snow test loads at 5,400 Pa, wind test loads reaching 2,400 Pa. However, the annual degradation rate is slightly different. Monocrystalline panels tend to lose 0.5-0.7% every year while polycrystalline panels break down at a rate of 0.6-0.8%. In warm climates, the difference is accentuated because of different temperature sensitivities.

Space Efficiency Requirements

Breaking down the usage of space, the required installation area is significantly different. To get a 6kW system, monocrystalline panels can be expected to cover 300-320 square feet and polycrystalline — 340-360 square feet. This 15% difference in terms of space utilization is especially important for installations with a small roof or space requirements.

Choosing Efficient Solar Panels for Your Needs

Choosing the best solar panel type requires you to consider the specifics of your situation to work out which type of panel is best for you. The first consideration is the available roof area and the size of the system required to cover your energy consumption. In limited-space installations, monocrystalline panels offer maximum power density, perhaps making up for higher initial costs through minimization of space needed for installation. When you are on a budget, keep in mind the value proposition over the long term – even though polycrystalline types are less expensive now, the gap in efficiency will be substantial over the life of the system. In addition to maximizing the benefits of their solar installations, many homeowners combine their solar with reliable battery storage solutions, such as EcoFlow’s line-up of portable power stations, for a steady source of power in the evenings or during grid outages. Climate is also important — monocrystalline may be best for high heat, with its superior heat tolerance tendency, and polycrystalline panels may have an advantage in locations with extensive cloud cover due to better performance in diffuse light conditions. Also think about how your house looks – monocrystalline tends to have a neat black look that matches well with contemporary buildings whereas you might like the blue look of a polycrystalline to fit in with a more traditional building. In the end, the right decision is a tradeoff between all these parameters and depends on your specific needs and priorities.

Making the Right Solar Investment Decision

The decision between monocrystalline or polycrystalline solar panels is based on one’s investment assumptions and budget limitations. Monocrystalline panels provide the highest efficiency (18-22%) and quality and have a longer lifespan at 20-25 years or more when compared with the amorphous and polycrystalline types. With their shiny black design and extended lifespan, the higher price is not a barrier to many homeowners. Polycrystalline panels are a bit less efficient at 15-17%, but are an equally great option and are suited for installations in a location with less diffused sunlight. Their lower first cost has made them an appealing choice for those larger installations where floor space wasn’t a demand. When making your choice, think about what’s right for you: available roof space, local weather, how you want your panels to look, and your long-term energy goals. To know for sure what the best panel for your needs will be, we’d recommend a consultation with a professional solar installer who can take a look at your property’s specific needs and recommend the right type of panel based on your needs and budget. This professional advice, along with the information gleaned after comparing the two, can ensure that your solar investment is one that will provide value for years to come.