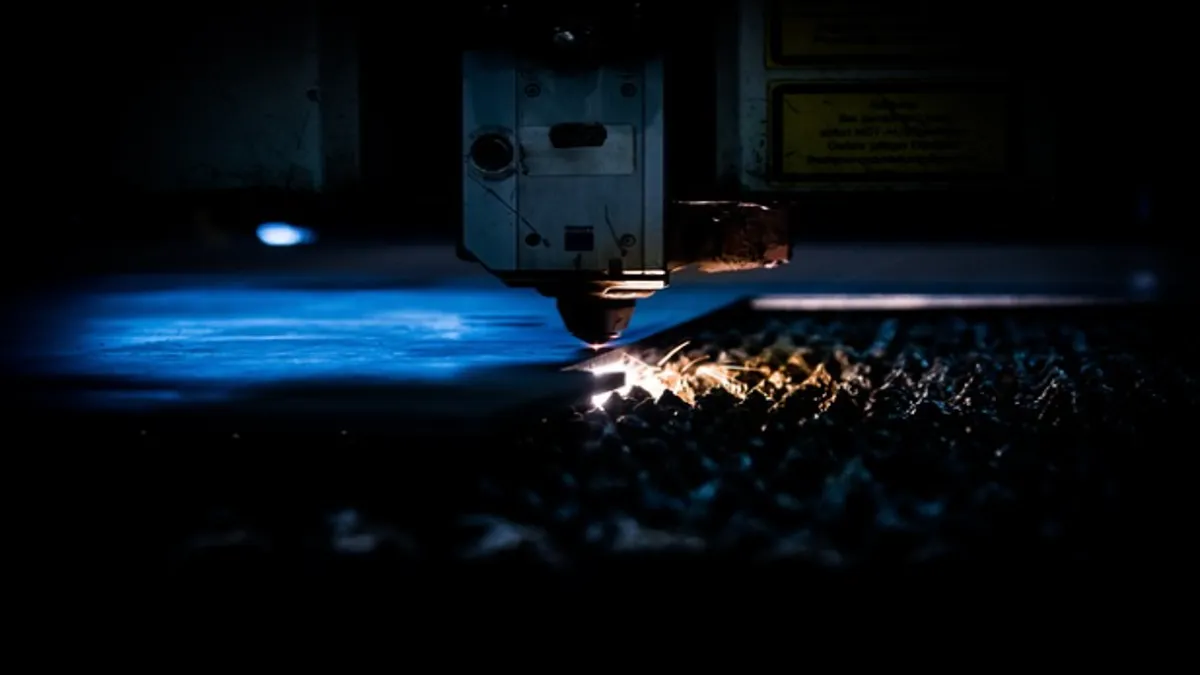

Metal is among the most durable and versatile materials that are widely used in industries, crafts, and products for everyday use. The demand for adding precise marks or custom designs on metal has become increasingly important, from personalized jewelry to industrial-grade tools. Here is where a laser engraver for metal is most needed. The laser engraving capability brings unmatched accuracy, efficiency, and flexibility, whether you are a hobbyist who likes to discover creative projects or a business that wants to expand production abilities.

In this article, we will discuss the major benefits of using laser engraving machines for metal, identify their most common usages, and even guide you on how to pick the one that suits you best. On our way, we are also going to talk about the Creality Falcon series, a line of cutting-edge laser engravers that has rapidly been getting recognized in the market.

Why Is a Laser Engraving Machine for Metal Better?

The need for precision and speed in today’s manufacturing has made traditional engraving methods less attractive. Laughing is very clear in certain ways.

1. High Precision and Detail

Laser technology enables one to create extremely fine details that are almost impossible to make with mechanical tools. Complex logos, barcodes, or decorative motifs can be carved, having even the smallest surface with very sharp edges of high contrast.

2. Durability of Marks

Laser engravings on metal are permanent and thus different from paint or stickers. They can be used in an environment of wear, heat, and also chemicals and hence are great for industrial products that require a long line of traceability.

3. Speed & Accuracy

It is very much possible for a laser engraving machine to accomplish a job in a fraction of the time that it would take an engraving tool to manually finish. The whole operation becomes a zero-labor, software-based one when the design is ready, thus saving considerable time and wages.

4. Versatility Across Metals

Almost every metallic material can be engraved by a metal engraver. Some top-notch machines go so far as to cut sheets of metal such as stainless steel or aluminum.

5. Low maintenance

The laser technique is a non-contact process, so there is very little wear on the equipment. This means that the maintenance will be less frequent than that of traditional mechanical tools.

Key uses of laser engraving in Metal

Laser engraving has become the go-to solution across the board for different companies, from artists’ studios to factory floors. Below are some of the most frequent applications:

1. Jewelry and Accessories

The technology of laser engraving enables jewelers to put clever patterns, initials, or custom graphics on rings, bracelets, and pendants. It acts like a double-edged sword: on one hand, it adds the uniqueness of each piece, and on the other, it keeps a perfect and clean surface.

2. Industrial Marking

One of the main uses for laser engravings in industry is for product tracking. Thus, the serial numbers, part codes, and compliance marks are incorporated on tools, machinery components, and electronics through the technique. These are the main sources of information for conferring and quality control.

3. Promotional Items

Most of the time, the engraved logo appears on metal pens, keychains, or drinkware to make long-lasting promotional merchandise, which is one of the favorite ways to represent brand identity and use the companies.

4. Art and Craft Projects

The use of laser engraving by artists and makers is limitless, as it allows them to develop imaginative designs on various types of metal plaques, ornaments, or decorative panels.

5. Medical Devices and Equipment

One of the major aspects where the healthcare industry depends a lot on identification is the safety of the patients. In order to keep the safety and traceability standards up to the required level, almost every instrument, implant, and surgical tool is accompanied by an engraved mark.

6. Automotive and Aerospace components

The metal parts in cars or planes are usually required to be marked in a way that the markings are durable enough to be used for compliance, identification of the part, and safety checks. Using laser engraving enables this to be done without any reduction in the strength of the materials.

Introducing Creality Falcon Laser Engravers

In contrast to the numerous brands dealing with the manufacturing of engraving tools, Creality is a name that has been getting more and more recognition over the last few years. Apart from 3D printing, Creality has decided to spread its wings also into the laser world by applying its groundbreaking concept.

The Falcon laser inventor line by Creality is created as a solution to the various user requirements; thus, it is the very first product range addressing the needs of users of both amateurs and experts. The highlight models include the ones mentioned below:

- Falcon CR: The CR is a perfect companion for people new to the world of laser engraving, with its easily operable functions while still preserving high precision.

- Falcon2: This equipment by Creality is a favorite choice of small businesses and artisans because of its stable operation and a powerful laser that allows a variety of metals to be engraved with the machine used in question.

- Falcon A1: The very A1 model is known for its wide application because it can be considered a perfect harmony of cheapness and most of the user-friendly features that pave the way both for the arts and for commercial activities.

- Falcon2 Pro: Regarded as a machine for professional engineers, the Pro model is equipped with enhanced performance, higher accuracy and faster speed, perfectly capable of executing large-scale projects

The Creality Falcon series has the most functional structure of all; it mainly keeps in balance the accessibility and the professional features of the machines. Their long life and safety functions, as well as the software compatibility, make the transition from one industry to another a piece of cake, as these machines are thus easily adapted.

How to Select the Right Laser Engraving Machine for Metal

Facing the myriad of alternatives, it can be a hard task to find a fittingly right machine. Here are a few necessary considerations to think about:

1. Power and Wavelength

The power of the laser defines the thickness and the cutting speed. Generally, for metal, a higher power level is more efficient. Besides that, the laser wavelength is also important because different metals have different absorptions of laser energy.

2. Engraving Area

The first thing to consider is the size of the projects that you want to work with. If you will be working on large metal sheets, then a machine with a larger working area will be suitable for you. However, if you want to do small and detailed work, then a compact machine will do.

3. Precision and Resolution

Resolution is characterized by dots per inch (DPI). More crisp details are produced when the resolution is higher, which is a must for getting detailed things such as logos, artworks, or micro texts to be visible.

4. Software Compatibility

First off, you have to know whether a machine supports the software you use for your designing. In general, engravers that are technically up-to-date can work nicely with common platforms like LightBurn or LaserGRBL, which are making the way from designing to engraving easier.

5. Cooling and Safety Features

One metal engraving should be a good cooling system, as it is a metal that is usually heated, and a small part of it is heated to make the metal engraving. Safety features such as protective shields, auto shutdown, and filters are just as important as cooling.

6. Budget vs. Usage

Even though high-end professional machines are fascinating and stunning and make your mouth water, you are going to use them beneficially only if you have extensive usage. A beginner or a hobbyist may be better off with a mid-range machine, while a business with a high demand should look at options like the Falcon2 Pro.

Future of Metal Engraving with Laser Technology

The success of laser etching is gradually becoming more evident. The transition towards automation and personalization that the industries are taking is one of the reasons for that. Laser machines are shrinking, getting economical, and becoming more user-friendly, so the small businesses, independent artists, and big factories are the ones that have access to this trend.

Just to be clear, the combination of smart software and better lasers will not only mean fewer mistakes and more options in the coming years but also that more industries will consider lasers as a solution. A company like Creality is already doing this with their Falcon series, and therefore both newbies and pros will have the same quality and access to the tools.

Conclusion

Metal laser engraving machines used to be something that was only found in big factories with large budgets. Such machines are now, however, widely used by jewelers, artists, manufacturers, and businesses that desire high precision and materials with permanence. It has enabled it to deliver various metals at tiny sizes, lasting as well as detailed, which has made it one of the most valuable tools of modern production and design.

When selecting a machine, the key factors that determine your machine should be the main factors of the power, the engraving area, precision, and safety, among the other features. The whole range of Creality Falcon models with their various versions and prices designed to meet the needs of beginners, makers, and professionals offers a simple but also efficient way. From Falcon CR up to Falcon2 Pro, these machines are the ideal illustration of how laser technology conquered accessibility in the high end of the performance realm.

FAQs

1. Can all metals be engraved with a laser machine?

Most common metals like steel, aluminum, brass, and titanium can be easily engraved with a laser machine, but the reflective ones may require a laser with high power.

2. What is the difference between engraving and etching?

Engraving is a process where the material is removed from the surface, and etching is a method that dissolves the top layer to make it look different.

3. Do I need a high-power laser for metal?

Yes, at least 20W is required for a metal product to be engraved clearly and efficiently.

4. Is laser engraving safe to do at home?

Yes, but you must wear safety gear, have good ventilation, and follow the guidelines given by the machine.

5. How do I choose the right Creality Falcon model?

The choice depends on the area of work: Falcon CR/A1 for beginners, Falcon2 for small businesses, and Falcon2 Pro for professional projects.