LED strip lighting has transformed the way architects, designers, and homeowners approach ambient and functional illumination. With its slim form factor, flexible installation, and energy efficiency, LED strip lighting continues to dominate modern architectural lighting. However, to achieve consistent light diffusion, better thermal performance, longer lifespan, and a professional-looking finish, LED strips need an essential companion — the LED aluminum profile.

Today, LED aluminum profiles have become a standard component in residential, commercial, and architectural lighting systems. They are no longer optional accessories but necessary elements that elevate both the performance and aesthetics of LED strip applications. In this complete guide, we explore what LED aluminum profiles are, why they matter, the different types available, where they are used, and how to select the right profile for your next lighting project.

What Is an LED Aluminum Profile?

An LED aluminum profile—also known as an LED extrusion, LED channel, or LED housing—is a specially designed aluminum channel used to install, protect, and enhance LED strip lights. It usually consists of:

- An extruded aluminum channel

- A diffuser cover (opal, frosted, semi-clear, or clear)

- End caps and mounting brackets

- Optional accessories such as suspension wires or corner connectors

These profiles serve several important functions. They create a clean and finished appearance, make installation easier, and significantly improve heat dissipation. Because LED strips generate heat during operation, especially high-density or high-power ones, aluminum profiles help draw heat away, ensuring stable operation and longer lifespan.

LED aluminum profiles also protect the LEDs from dust, moisture, abrasion, and accidental damage while delivering a more refined, uniform beam of light.

Why LED Aluminum Profiles Matter

LED aluminum profiles provide several functional and aesthetic advantages that make them essential for any professional lighting installation.

1. Superior Heat Dissipation

LED strip lights—especially high-density SMD, or high-wattage versions—can experience significant heat buildup. Excess heat accelerates lumen depreciation and shortens the LED’s lifespan. Aluminum, being an excellent thermal conductor, dissipates heat efficiently, keeping the LEDs cool and stable.

2. Improved Lighting Quality

With the use of a frosted or opal diffuser, LED aluminum profiles soften harsh LED dots and create a smooth, even beam. This is important for applications that require visual comfort, such as under-cabinet lighting, display lighting, or architectural accent lighting.

3. Professional and Clean Finish

Instead of exposed LED strips taped under shelves or cabinets, aluminum profiles provide a sleek, integrated look. Whether recessed into ceilings, mounted under cabinets, or installed along staircases, they elevate the lighting to a professional architectural standard.

4. Extended LED Lifespan

By maintaining a lower operating temperature and protecting the strip from dust, impact, and environmental factors, LED aluminum profiles significantly increase LED durability and performance consistency.

5. Installation Flexibility

LED aluminum profiles support numerous installation styles—surface, recessed, suspended, corner-mounted, or even outdoor waterproof applications. This versatility is why they are widely used by lighting designers and contractors worldwide.

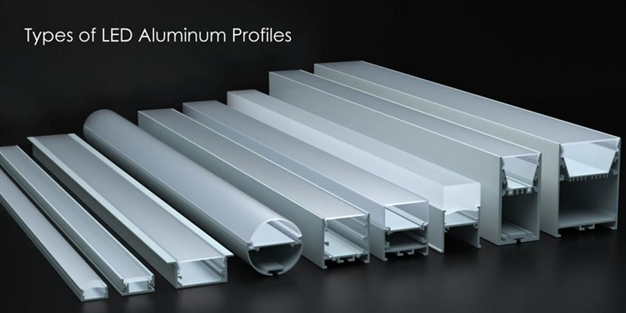

Common Types of LED Aluminum Profiles

There are many types of LED profiles, each designed for a specific lighting effect or installation condition. Below are the most commonly used categories:

1. Surface-Mounted LED Aluminum Profiles

These are the most versatile and easiest to install. They can be mounted on walls, ceilings, shelves, cabinets, or any flat surface. They are ideal for general lighting, accent lighting, and furniture lighting.

2. Recessed LED Profiles

Designed to sit flush within surfaces, recessed profiles are popular in architectural lighting. They are used in ceilings, walls, floors, cabinetry, and drywall. They create clean linear light lines and require precise installation.

3. Corner (45-Degree) Profiles

Perfect for room corners, under-cabinet edges, or shelf lips, these profiles direct the light at a 45-degree angle. They are widely used for indirect lighting, task lighting, and display illumination.

4. Deep Profiles for Dotless Lighting

Deep aluminum channels paired with high-density SMD LED strips or COB LED strips create 100% dotless, continuous illumination. These profiles are popular for premium projects, including hotels, showrooms, and luxury residences.

5. Suspended Linear Profiles

These wider, deeper extrusions are used to create pendant-style linear luminaires for offices, studios, conference rooms, and retail environments. They offer both direct and indirect lighting options.

6. Round or Tube Aluminum Profiles

These provide decorative illumination and can be used as architectural pendant fixtures, outdoor tubes, or vertical light columns.

7. Waterproof or Outdoor Profiles

Equipped with sealed covers and gaskets, these profiles provide weather protection and are suitable for gardens, pathways, building facades, and outdoor signage.

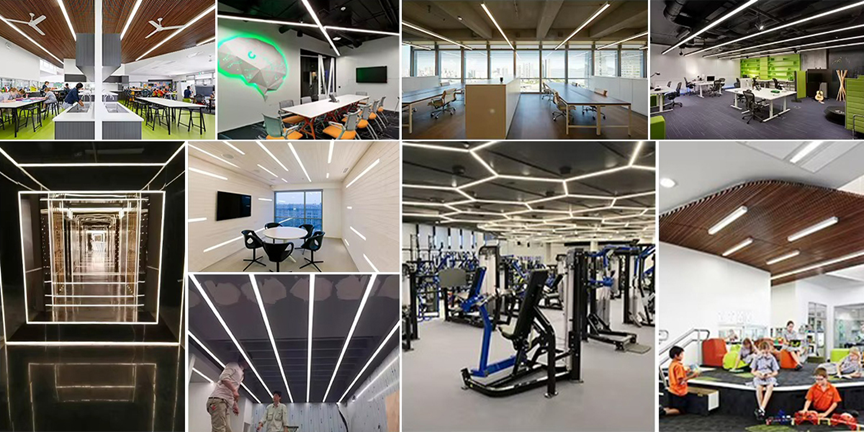

Where LED Aluminum Profiles Are Used

LED aluminum profiles are now used across almost every lighting environment—including residential, commercial, and industrial applications. Common use cases include:

- Kitchen under-cabinet lighting

- Wardrobe and closet lighting

- Retail shelf and showcase illumination

- Hotel lobby and corridor lighting

- Residential cove, stair, and accent lighting

- Office linear lighting fixtures

- Architectural wall washing

- Display and exhibition lighting

- Signage and backlighting

- Outdoor landscape or facade lighting (with waterproof profiles)

Their versatility and aesthetic appeal make them an essential component for designers who want a combination of function and elegance.

How to Choose the Right LED Aluminum Profile

Selecting the right LED aluminum profile is not just about choosing a channel that fits the LED strip. For architects, lighting designers, and contractors, the selection process involves evaluating thermal performance, optical behavior, installation constraints, long-term maintenance, and desired lighting experience. Below is an expanded, professional-level checklist to guide precise specification.

1. Match the Profile to the LED Strip Width, Wattage, and Density

The physical fit between the LED strip and the channel is the most fundamental factor—but the professional selection goes beyond width. You must consider LED chip type, density, and heat generation.

Common LED Strip Widths

- 8mm → Mini COB, 2835 strips for furniture and decorative applications

- 10mm → Standard 2835/5050 SMD strips used in most architectural lighting

- 12mm → High-density or higher-wattage COB/SMD strips requiring larger heat sinks

- 15mm–20mm → RGBW, tunable white, ultra-high-brightness commercial strips

Heat Output Considerations (W/M vs. Profile Depth)

- <10W/m → Regular surface profiles are sufficient

- 10–15W/m → Prefer medium-depth profiles with thicker walls

- 15–20W/m → Use deep or heavy-duty aluminum profiles for heat dissipation

- >20W/m → Must use high-mass aluminum extrusions; consider ventilation and thermal paste

Rule of thumb:

Higher wattage + high LED density = deeper or wider aluminum profile required.

This ensures:

- Stable junction temperature (Tj)

- Longer LED lifespan

- Stable color temperature over time

- Reduced lumen degradation

2. Determine the Desired Light Output and Visual Effect

The profile directly shapes how light is perceived. Defining the visual purpose early ensures proper extrusion selection.

Questions for Designers

- Should the light be dotless, uniform, and visually soft?

- Should the output be high-brightness for task use?

- Do you want a wide beam, narrow beam, or side-directed light?

- Is the lighting functional, decorative, or architectural?

Profile Depth vs. Visual Result

- Deep profiles (≥15mm) → Perfectly even illumination, zero dots, ideal for luxury environments

- Shallow profiles (7–10mm) → Higher brightness, visible LED points, suitable for functional lighting

Application Guidelines

- Ambient lighting → Wide or deep profiles

- Task lighting → Shallow with clear cover for maximum intensity

- Accent lighting → Corner profiles or narrow-beam extrusions

- Feature light lines → Recessed deep channels to emphasize architectural geometry

3. Choose the Right Diffuser Based on Optical Behavior

The diffuser determines beam shape, brightness, and visual comfort. Different environments require different diffuser characteristics.

Clear Diffusers

- Highest brightness output

- Suitable for task lighting or indirect applications

- LED dots remain visible

- Ideal when maximum lumen efficacy is needed

Frosted Diffusers

- Balanced between brightness and diffusion

- Reduces glare

- Good for general illumination and commercial settings

- Works well with medium-density LED strips

Opal / Milky Diffusers

- Best diffusion, zero hotspots

- Achieves premium “continuous line of light”

- Slightly lower brightness

- Ideal for hotels, luxury homes, high-end retail

Specialty Diffusers

- Prismatic lenses for soft but high-efficiency output

- Side-light diffusers for shelving edge lighting

- Anti-glare diffusers for working spaces

4. Consider the Installation Method and Architectural Integration

The installation constraints often determine the extrusion type.

Surface-Mounted Profiles

- Easiest to install

- Suitable for retrofits or furniture projects

- Flexible positioning without structural modification

Recessed Profiles

- Create flush, integrated architectural light lines

- Require routing or cutting into surfaces (ceilings, drywall, cabinetry)

- Offer the cleanest, most minimalist aesthetic

Suspended Profiles

- Used to create linear pendant luminaires

- Often house LED drivers inside

- Perfect for offices, galleries, and modern interior design

Corner Profiles (45°)

- Direct light diagonally

- Used under cabinets, shelves, or architectural edges

- Reduce glare while highlighting structural lines

Bendable / Flexible Profiles

- Follow curved surfaces, arcs, or columns

- Ideal for creative or sculptural designs

Correct installation method ensures alignment, stability, and compliance with project requirements.

5. Evaluate the Application Environment (Indoor, Outdoor, Humidity, Heat)

Environmental conditions directly affect profile selection, especially for durability and safety.

Indoor Conditions

- Standard aluminum + PC diffusers are sufficient

- Consider opal diffusers for visual comfort

Outdoor / Wet Environments

Choose:

- UV-stable PC diffusers (PMMA may yellow outdoors)

- Sealed end caps and silicone gaskets

- IP65–IP67 waterproof LED strips

- Corrosion-resistant aluminum finishes

High-Temperature Environments

Areas near:

- Kitchens

- Machinery

- Enclosed ceilings with poor airflow

Require:

- Heavier aluminum heat sinks

- Ventilation-friendly designs

Commercial High-Usage Areas

Lighting that’s on 12–24 hours daily should always use profiles with excellent thermal mass.

6. Length Requirements, Continuity, and Seamless Light Lines

Long linear lighting is one of the biggest reasons designers choose aluminum profiles.

Considerations for Long Runs

- Most extrusions come in 2–3m lengths; longer lines require connectors

- Choose profiles with strong alignment pins for seamless joints

- Use COB strips to avoid visible breaks in light continuity

- Ensure the diffuser is available in matching lengths to avoid seams

For premium projects requiring 5–20m continuous runs, deep profiles + COB LED strips + high-quality diffusers produce the best result.

7. Driver Integration and Electrical Planning

Electrical compatibility is often overlooked but critical.

For Compact Installations

- Ensure the profile has space for cable routing

- Check whether the strip can be powered from one end or requires dual-end feed

For Suspended Profiles

- Many extrusions can house drivers internally

- Verify:

- Internal cavity height

- Thermal isolation from LEDs

- Ease of driver replacement

- Cable exit options

For RGB/RGBW/Tunable White

- Wider channels (12–20mm) are necessary

- Ensure diffusers can blend multi-color LEDs into uniform output

Correct driver planning ensures stability, safety, and long-term reliability of the lighting system.

Where to Find High-Quality LED Aluminum Profiles

If you are looking for reliable, professional-grade LED aluminum profiles with a wide selection of mounting styles and sizes, you can explore the full product range at LED aluminium profile.

This collection includes surface-mounted, recessed, corner, deep, suspended, and waterproof options suitable for both residential and commercial lighting projects.

Conclusion

LED aluminum profiles have become indispensable for modern lighting design. They ensure better thermal performance, elevated visual quality, and a polished architectural finish. Whether you’re a lighting designer, contractor, or homeowner, choosing the right LED aluminum profile can completely transform the functionality and aesthetics of your LED strip installation.

As lighting trends continue shifting toward minimalism, linear lighting, and smart illumination, LED aluminum profiles will continue to play a critical role in shaping beautiful and durable lighting projects.