In the world of polymer manufacturing, few terms are as foundational—and as often misunderstood—as the blow-up ratio. Though it sounds abstract, this ratio plays a central role in determining the physical properties, durability, and quality of plastic films used in everything from food packaging to industrial liners. For engineers, plant operators, and product designers, understanding the blow-up ratio is essential—not just to optimize performance, but also to ensure efficiency, safety, and sustainability in production.

So, what exactly is the blow-up ratio, and why does it matter so much in film extrusion? In this article, we explore its technical definition, practical implications, and broader importance across polymer applications.

What Is the Blow-Up Ratio?

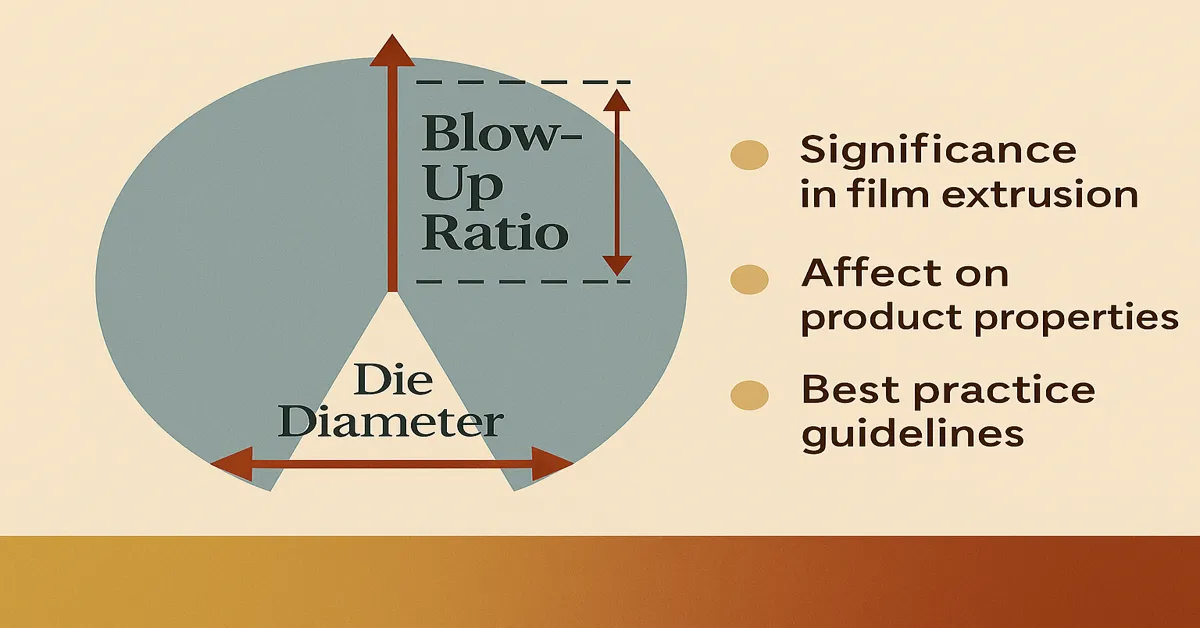

Blow-up ratio (BUR) is a key geometric and operational parameter in blown film extrusion, a process used to manufacture thin plastic films. The ratio itself is defined as:

Blow-Up Ratio (BUR) = Bubble Diameter / Die Diameter

In other words, it measures how much the molten plastic film expands in width after it exits the extrusion die and is inflated into a bubble. A BUR of 2:1, for instance, means the diameter of the bubble is twice the diameter of the die.

This simple ratio has wide-ranging implications. It affects film strength, thickness uniformity, clarity, orientation, and mechanical properties. Choosing the right BUR is both an art and a science, deeply dependent on polymer type, end-use requirements, and downstream processing conditions.

The Blown Film Extrusion Process: A Brief Overview

To grasp the significance of the blow-up ratio, it’s helpful to first understand the process it belongs to:

- Polymer Feed – Plastic pellets (usually polyethylene or polypropylene) are fed into an extruder.

- Melting – Heat and mechanical shear melt the polymer, which is then pushed through a circular die.

- Film Formation – The molten polymer exits the die as a thin tube, which is immediately inflated with air to form a large bubble.

- Cooling and Solidification – Air rings or cooling systems cool the bubble. Rollers collapse it into flat film.

- Winding – The flattened film is wound onto rolls for cutting, printing, or packaging.

Throughout this process, the expansion of the bubble defines the final film width and significantly influences its orientation and mechanical behavior—hence the importance of the blow-up ratio.

Why the Blow-Up Ratio Matters

1. Film Strength and Orientation

When the film is inflated, the stretching of the polymer in the transverse direction (TD) introduces molecular orientation. The higher the BUR, the more orientation in TD. This affects:

- Tensile strength

- Tear resistance

- Puncture durability

Orientation can enhance these properties in one direction but may reduce them in the perpendicular direction, creating a balance trade-off in mechanical design.

2. Thickness Uniformity

A poorly selected blow-up ratio can cause gauge variation, leading to film areas that are too thin or thick. This becomes problematic in applications like lamination or printing, where consistency is critical.

3. Clarity and Optical Properties

Films blown at higher ratios tend to have more haze due to orientation-induced crystallinity. In contrast, lower BURs often yield clearer films. The desired transparency depends on product type—packaging films for display items need clarity, while industrial films may prioritize strength.

4. Shrinkage and Stability

The blow-up ratio also impacts thermal shrinkage during further processing. Films with high orientation shrink more when exposed to heat. This is a design consideration for shrink wraps or form-fill-seal films.

Common Blow-Up Ratios and Their Uses

BUR typically ranges from 1.5:1 to 4:1, though values outside this range exist in specialized processes.

| Blow-Up Ratio | Typical Use Case | Properties |

|---|---|---|

| 1.5:1 to 2.0:1 | Heavy-duty films, industrial liners | High strength, low shrinkage |

| 2.5:1 to 3.0:1 | General packaging films | Balanced orientation and clarity |

| 3.0:1 to 4.0:1 | Stretch films, shrink wrap | High orientation, better TD strength |

Some specialty films, such as biaxially oriented films, use additional stretching techniques beyond BUR to enhance mechanical properties.

Blow-Up Ratio vs. Draw-Down Ratio

While the blow-up ratio measures transverse (width-wise) expansion, the draw-down ratio (DDR) measures longitudinal (machine-direction) stretching:

Draw-Down Ratio = Die Gap / Final Film Thickness

Together, BUR and DDR define the biaxial orientation of the film—a key determinant of final performance. A high DDR with a low BUR, for example, results in strong MD orientation and weak TD properties.

Balancing these ratios is a complex task requiring input from materials science, production engineering, and product design.

The Science Behind the Ratio: Molecular Orientation

Why does stretching a plastic bubble change its properties?

The answer lies in polymer chain alignment. When a polymer is melted, its molecular chains are randomly arranged. Stretching aligns them in the direction of pull. This:

- Increases tensile strength along the stretch

- Reduces elongation (film becomes stiffer)

- Alters barrier properties (affecting moisture/oxygen transmission)

- Changes optical behavior

Thus, BUR isn’t just about dimensions—it’s about engineering the internal structure of a film to achieve desired characteristics.

Factors Influencing the Optimal Blow-Up Ratio

1. Polymer Type

Different resins behave differently under stretch. For example:

- LDPE can tolerate high BURs without tearing

- HDPE tends to resist stretching and may require lower BUR

- PP is sensitive to orientation and often demands precise control

2. Film Application

What is the film used for? A grocery bag needs strength and tear resistance. A greenhouse film might need light diffusion and weatherability. Each use case suggests a different BUR.

3. Cooling Rate

Faster cooling “freezes” the polymer in its stretched state. Slower cooling allows relaxation, affecting the final orientation. Cooling systems must be tuned to match the BUR.

4. Die Design and Air Stability

Larger BURs require stable air rings, optimized die lips, and precision tension control. Otherwise, the bubble may wobble, causing gauge variation or catastrophic rupture.

Blow-Up Ratio and Sustainable Manufacturing

In recent years, manufacturers have faced pressure to reduce material use, increase recyclability, and optimize energy efficiency. BUR plays a role in all of these goals:

– Thinner Films

High BUR allows for thinner films with equal or better performance due to orientation, reducing resin use.

– Mono-Material Films

With proper orientation, mono-material films can mimic multilayer performance, aiding recyclability.

– Lower Energy Use

Optimized BUR can reduce cooling and heating requirements, improving energy efficiency.

As such, BUR is an optimization tool, not just a process parameter. It supports sustainability and product innovation.

Measuring and Controlling the Blow-Up Ratio

BUR must be continuously monitored and precisely controlled during production. This is typically done using:

- Infrared sensors or laser micrometers to measure bubble diameter

- Real-time process feedback systems integrated with control panels

- Manual calibration using periodic measurements and film width checks

Advanced lines employ closed-loop systems that automatically adjust inflation pressure or die speed to maintain a stable BUR throughout a production run.

Common Problems and Solutions

Problem 1: Bubble Instability

Cause: Incorrect BUR, poor air ring balance

Solution: Reduce BUR slightly, improve air distribution

Problem 2: Gauge Variation

Cause: Uneven expansion, bubble flutter

Solution: Stabilize tower conditions, adjust BUR or DDR

Problem 3: Film Tearing

Cause: Resin overstretched, high BUR on brittle materials

Solution: Reduce BUR, modify resin blend

Problem 4: Poor Optical Quality

Cause: High orientation haze

Solution: Lower BUR, adjust cooling rate or use optical-grade resin

Real-World Example: Choosing a Blow-Up Ratio for a Retail Film

Imagine a packaging company tasked with producing transparent produce bags. The customer requires clarity, moderate strength, and thin gauge. The engineer considers:

- LDPE resin for clarity

- BUR of 2.5:1 for balanced orientation

- DDR of 4.0:1 to achieve desired thickness

This combination ensures mechanical integrity, optical quality, and cost-efficiency. A small change in BUR (e.g., 3.0:1) might yield stronger TD properties but compromise clarity. It’s a design trade-off.

Looking Ahead: The Future of Blow-Up Ratio Optimization

As the film extrusion industry grows more digitized, expect machine learning and AI tools to take over BUR optimization. Algorithms can analyze polymer rheology, temperature, line speed, and historical data to recommend the ideal ratio for new materials or formats.

Also, the rise of biopolymers (like PLA or starch blends) will require new BUR strategies, as these materials behave differently from petrochemical resins.

Conclusion: Why the Blow-Up Ratio Deserves Attention

The blow-up ratio might seem like a narrow technical metric, but it is, in truth, a linchpin in the performance and efficiency of plastic film production. It shapes the mechanical properties, optical appearance, cost, and sustainability of the final product. Whether you’re a polymer scientist, process engineer, or sustainability consultant, understanding and leveraging BUR is essential to competitive, responsible manufacturing.

In a world demanding smarter materials and leaner processes, the future of film extrusion will not just be shaped by what we make—but by how well we manage ratios like this one.

FAQs

1. What is the blow-up ratio in film extrusion?

The blow-up ratio (BUR) is the ratio of the bubble diameter to the die diameter in blown film extrusion. It measures how much the film is expanded in the transverse direction after exiting the die.

2. Why is the blow-up ratio important in film production?

BUR directly affects the mechanical strength, thickness uniformity, clarity, and orientation of the final film. It is a critical parameter for optimizing product performance and production efficiency.

3. What is a typical blow-up ratio range?

Most applications use a BUR between 1.5:1 and 4:1. Lower ratios are common for industrial films; higher ratios are used for packaging and shrink films requiring more orientation.

4. How does the blow-up ratio impact film clarity?

Higher BURs increase molecular orientation, which can cause haze and reduced clarity. Lower BURs generally produce clearer films by minimizing crystallinity.

5. Can adjusting the blow-up ratio improve film strength?

Yes. Increasing the BUR enhances transverse direction strength, while combining it with draw-down ratio (DDR) allows for balanced biaxial orientation to meet specific strength requirements.