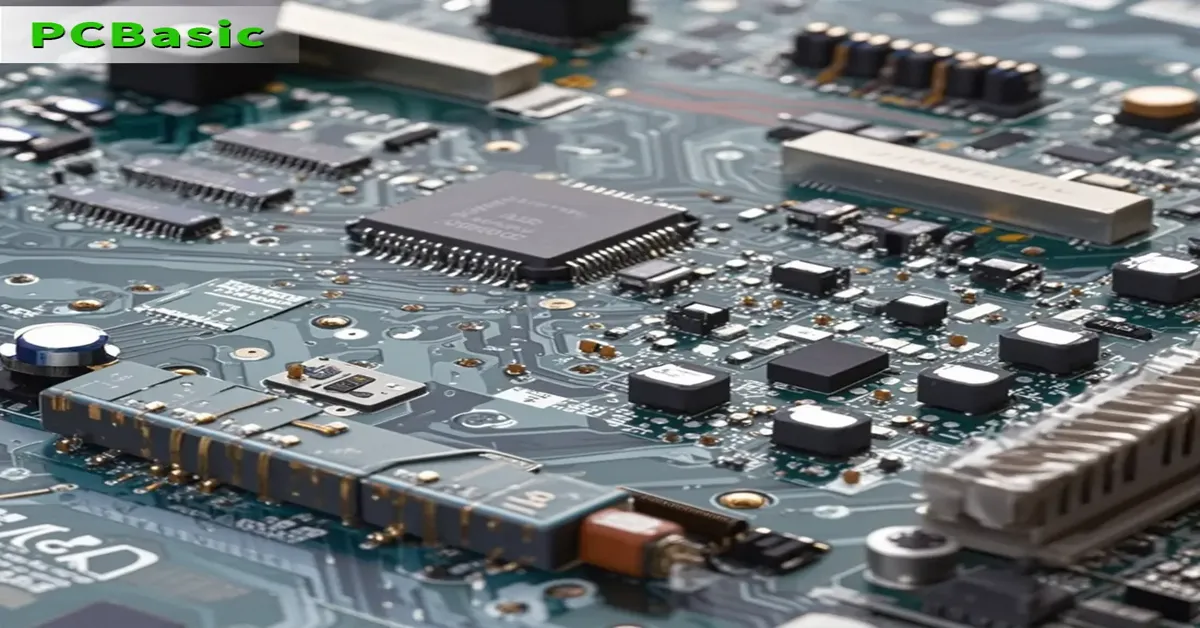

Circuit board assembly is a vital step that brings electronic designs to life. Without it, a printed circuit board (PCB) is just a platform with copper traces — no functionality, no performance, no product. In this article, we’ll walk through what circuit board assembly is, the main techniques used, and how to ensure your PCB assembly meets today’s high standards for quality and reliability.

What is Circuit Board Assembly?

Circuit board assembly is the process of attaching and soldering electronic components onto a PCB to form a complete working circuit. The finished product is often referred to as a printed circuit board assembly (PCBA). This assembly is what powers the devices we use every day — from smartphones and laptops to cars and medical equipment.

Circuit board assembly involves both advanced machinery and precise engineering to ensure that every component is placed accurately and securely.

Key Circuit Board Assembly Techniques

Surface Mount Technology (SMT)

SMT is the most common assembly method today. Components are mounted directly onto the surface of the board without the need for drilled holes. SMT enables high-speed automated assembly and allows for more compact, lightweight designs.

Through-Hole Technology (THT)

In THT, components have leads that pass through pre-drilled holes in the board and are soldered on the opposite side. This method provides strong mechanical bonds and is still preferred for applications requiring durability, such as automotive and industrial systems.

Hybrid Assembly

Some assemblies combine both SMT and THT. This approach is used for boards that need a mix of high-density surface components and robust through-hole parts.

The Circuit Board Assembly Process: Step by Step

Here’s what typically happens during circuit board assembly:

1. Solder paste printing — Solder paste is applied to the board’s pads using a stencil.

2. Component placement — Pick-and-place machines or operators place components on the board.

3. Soldering — Reflow ovens solder SMT components; wave or selective soldering is used for through-hole parts.

4. Inspection — Automated optical inspection (AOI), X-ray inspection, and electrical testing check for defects and ensure correct assembly.

5. Cleaning and coating (if required) — Boards are cleaned to remove residues and may receive conformal coating or potting for environmental protection.

Why Circuit Board Assembly Quality is So Important

High-quality circuit board assembly ensures:

- Consistent device performance

- Long-term reliability in the field

- Compliance with industry standards (such as IPC-A-610, ISO 9001, IATF 16949)

Defects like cold solder joints, bridging, or missing components can cause failures, costly repairs, and damage to your brand’s reputation.

Circuit Board Assembly Applications

You’ll find circuit board assemblies in:

- Consumer electronics (smartphones, tablets, wearables)

- Automotive electronics (ECUs, sensor modules)

- Medical equipment (monitors, diagnostic tools)

- Industrial automation (robotics, controllers)

- Telecommunications and networking equipment

How to Select the Right Circuit Board Assembly Partner

When choosing a supplier for circuit board assembly, consider:

- Manufacturing capabilities — Can they handle complex, multilayer, or high-density boards?

- Quality certifications — Look for ISO 9001, IATF 16949, ISO 13485, or relevant industry standards.

- Testing and inspection — Do they offer comprehensive testing (AOI, X-ray, functional testing)?

- Component sourcing — Do they use original, traceable components?

- Production flexibility — Can they support both prototypes and large-scale production?

Conclusion

Circuit board assembly is the key step that transforms your circuit design into a functional reality. A solid understanding of the process, techniques, and quality requirements helps you produce reliable electronic products. Choosing the right assembly partner is just as important as a good design — it ensures your devices work as expected, every time.