Liquid Silicone Injection Molding (LIM) is revolutionizing the manufacturing industry with its precision, efficiency, and versatility. Whether you’re in the automotive, medical, electronics, or consumer goods sectors, understanding this process can help you produce better, safer, and more reliable products.

What Is Liquid Silicone Injection Molding?

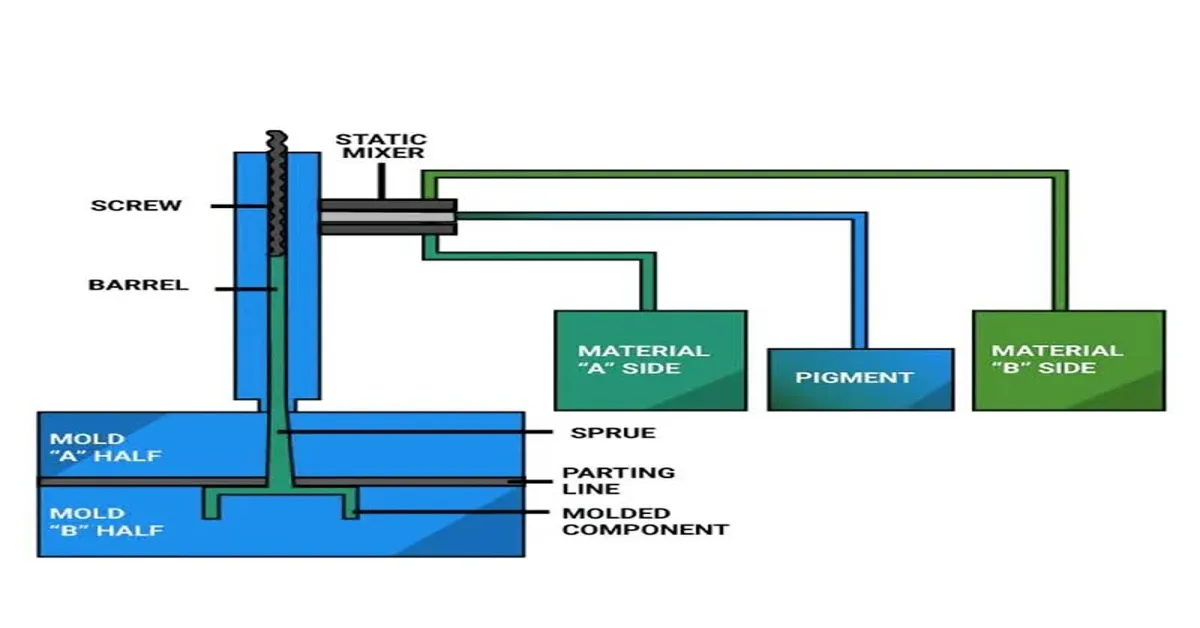

Liquid Silicone Injection Molding is a process used to create rubber-like, flexible parts using high-purity, two-part silicone compounds. These parts are typically used in demanding environments due to their exceptional durability and thermal stability.

How Does the LIM Process Work?

Step-by-Step Overview

- Material Preparation: Two liquid silicone components (Part A and Part B) are mixed.

- Injection: The mixture is injected into a heated mold at high pressure.

- Curing: The silicone cures inside the mold, forming a solid elastomer.

- Demolding: The finished product is ejected from the mold.

This entire process is highly automated, ensuring precision and consistency.

Benefits of Liquid Silicone Injection Molding

1. Excellent Heat Resistance

Silicone rubber maintains stability across a wide temperature range, from -55°C to +300°C, making it ideal for harsh environments.

2. Biocompatibility

LIM is commonly used in medical applications due to its hypoallergenic and non-toxic properties.

3. Flexibility and Durability

The material can withstand stress, strain, and repeated use without deforming.

4. Complex Geometry Capabilities

Thanks to its low viscosity and flowability, liquid silicone can fill intricate mold cavities, making it ideal for producing small, detailed parts.

Common Applications of LIM

Medical Industry

- Catheters

- Seals and gaskets

- Infant products (pacifiers, bottle nipples)

Automotive Sector

- Electrical connectors

- Grommets

- Sensor covers

Consumer Goods

- Wearables

- Kitchenware

- Personal care products

Liquid Silicone Material Properties

Thermal Stability

LIM parts can withstand continuous exposure to high temperatures without degradation.

Electrical Insulation

LIM materials offer excellent electrical resistance, making them suitable for electrical and electronic applications.

Chemical Resistance

Silicone resists water, oxidation, and many chemicals, increasing its durability in challenging environments.

LIM Tooling: What You Need to Know

Tooling is a critical component of the LIM process. High-quality molds are typically made of steel and designed to withstand thousands of production cycles.

Key Considerations

- Precision Design: Ensures tight tolerances.

- Venting: Helps air escape for defect-free parts.

- Temperature Control: Uniform heating is essential for curing.

Automation in Liquid Silicone Injection Molding

Automation is a key advantage of LIM. From material mixing to injection and demolding, the process is highly automated.

Benefits of Automation

- Reduced labor costs

- Improved consistency

- Faster cycle times

- Enhanced safety

This makes LIM particularly attractive for high-volume manufacturing.

Quality Control in LIM Manufacturing

Maintaining high quality is essential, especially in regulated industries like medical and aerospace.

Common QC Measures

- Visual inspection

- Dimensional verification

- Material traceability

- Functional testing

Using advanced monitoring systems ensures that every part meets strict specifications.

Design Tips for LIM Parts

When designing parts for LIM, keep the following best practices in mind:

Uniform Wall Thickness

Maintains even curing and reduces defects.

Avoid Undercuts

Undercuts complicate demolding; try to minimize or design around them.

Use Radii Instead of Sharp Corners

Improves material flow and part strength.

Include Venting and Gating Features

Ensures complete filling and reduces air entrapment.

Future of Liquid Silicone Injection Molding

With the rise of miniaturization, wearable tech, and biocompatible devices, LIM will continue to grow. Advances in 3D printing of silicone and hybrid materials are also expanding the possibilities.

Trends to Watch

- Micro-molding for electronics and sensors

- Smart silicones with embedded functions

- Improved automation and AI in molding machines

Conclusion

Liquid Silicone Injection Molding is an advanced, efficient, and versatile process ideal for producing high-quality parts in various industries. With benefits such as excellent durability, precision, and biocompatibility, LIM is poised to remain a vital manufacturing method in the years ahead.Whether you’re designing medical devices, automotive components, or consumer products, understanding the LIM process can help you make smarter decisions, reduce production costs, and improve product quality.