Measurement is a fundamental part of human life, science, and industry. From ancient civilizations using rudimentary sticks to measure land, to today’s advanced digital devices capable of nanometer-level precision, the evolution of measurement instruments has shaped the way humans explore, build, and innovate. These tools allow us to quantify physical quantities such as length, mass, temperature, pressure, time, and electrical parameters with accuracy and repeatability. Whether used in laboratories, manufacturing plants, construction sites, or daily life, measurement instruments are essential for ensuring quality, safety, and efficiency.

This article explores the concept, types, functions, and applications of measurement instruments, as well as their importance in modern society.

Understanding Measurement Instruments

A measurement instrument is a device or tool used to determine the value or magnitude of a physical quantity. The measurement process involves comparing the quantity being measured against a standard or known reference. The instrument then outputs the measurement in a readable format, such as a scale, digital display, or recorded data.

The performance of a measurement instrument depends on three key qualities:

- Accuracy – How close the measured value is to the actual or true value.

- Precision – The repeatability or consistency of the measurement results.

- Resolution – The smallest change in the measured quantity that the instrument can detect.

Measurement instruments can be simple mechanical devices, like rulers and weighing scales, or complex electronic systems, like laser interferometers and digital oscilloscopes.

Historical Development of Measurement Instruments

The origins of measurement instruments can be traced back thousands of years. Ancient Egyptians used cubit rods to measure length for construction. Early civilizations also developed sundials and water clocks to track time. The invention of balance scales marked a breakthrough in mass measurement.

The industrial revolution in the 18th and 19th centuries brought major advancements in measurement tools, especially for engineering and manufacturing. Standardization became critical, leading to the creation of measurement systems like the metric system. In the 20th and 21st centuries, electronics, computing, and sensor technologies transformed measurement instruments, allowing for automated, high-speed, and high-precision measurements.

Categories of Measurement Instruments

Measurement instruments can be classified into different categories based on the physical quantity they measure. Below are some major types:

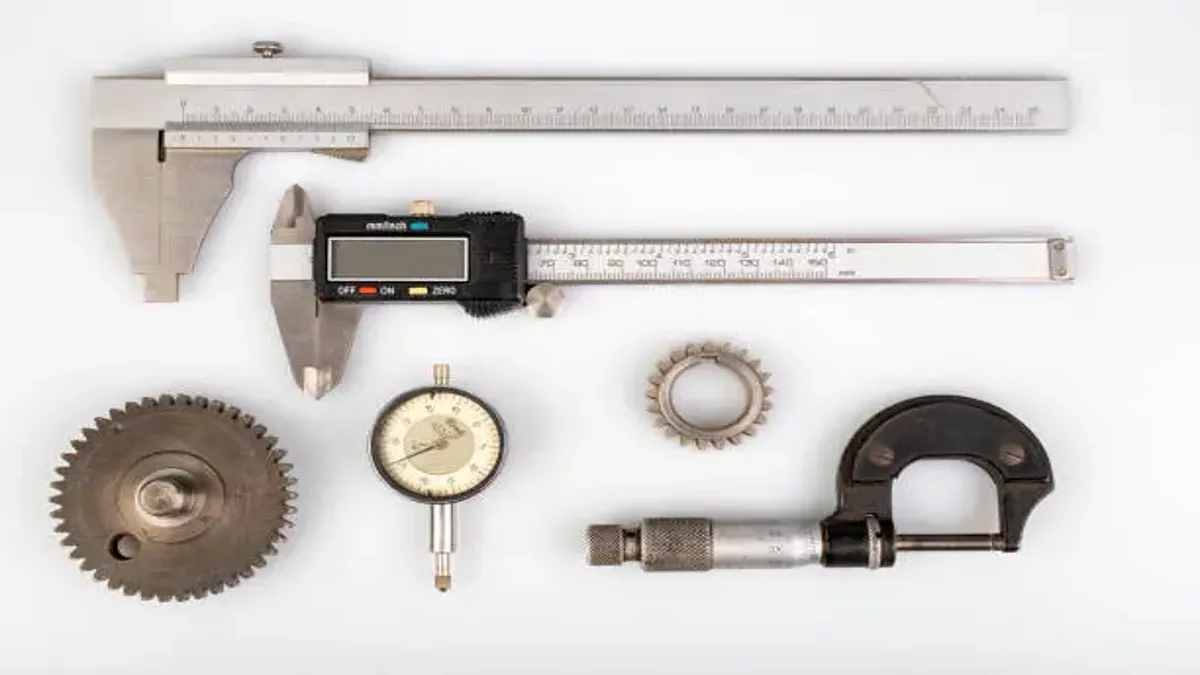

Length and Distance Measurement Instruments

These instruments measure linear or angular dimensions. Common examples include:

- Rulers and Tape Measures – Basic tools for everyday measurements.

- Vernier Calipers – Precision instruments capable of measuring small dimensions with an accuracy of 0.02 mm or better.

- Micrometers – Designed for extremely fine measurements, often used in mechanical engineering.

- Laser Distance Meters – Use laser technology for quick, contactless distance measurements.

- Coordinate Measuring Machines (CMMs) – Advanced systems for measuring complex geometries in manufacturing.

Mass and Weight Measurement Instruments

Mass measurement is crucial in trade, science, and industry. Examples include:

- Spring Scales – Measure weight based on spring deflection.

- Analytical Balances – Used in laboratories for highly precise mass measurements.

- Digital Weighing Scales – Common in retail and logistics for quick readings.

- Load Cells – Electronic sensors that measure weight or force in industrial applications.

Time Measurement Instruments

Measuring time accurately is essential for everything from navigation to scientific experiments.

- Mechanical Clocks and Watches – Traditional devices based on gears and springs.

- Digital Clocks – Use quartz crystals or atomic standards.

- Stopwatches – For recording elapsed time with precision.

- Atomic Clocks – The most accurate timekeeping devices, used in GPS and telecommunications.

Temperature Measurement Instruments

Temperature affects almost every physical and chemical process.

- Mercury-in-Glass Thermometers – Traditional devices still used in certain applications.

- Digital Thermometers – Provide instant and easy-to-read results.

- Infrared Thermometers – Measure temperature without direct contact.

- Thermocouples and RTDs – Used in industrial and scientific environments for high-accuracy temperature readings.

Pressure Measurement Instruments

Pressure measurements are essential in weather forecasting, engineering, and fluid mechanics.

- Barometers – Measure atmospheric pressure.

- Manometers – Measure pressure in gases or liquids using a column of fluid.

- Bourdon Tube Gauges – Common in industrial applications for fluid and gas pressure measurement.

- Digital Pressure Sensors – Provide high-precision data for automated systems.

Electrical Measurement Instruments

Electrical quantities like voltage, current, and resistance require specialized instruments.

- Multimeters – Versatile devices measuring voltage, current, and resistance.

- Oscilloscopes – Display electrical waveforms over time.

- Clamp Meters – Measure current without breaking the circuit.

- Power Meters – Measure power consumption and efficiency in electrical systems.

Specialized Scientific Measurement Instruments

In scientific research, many instruments are designed for specific purposes.

- Spectrometers – Analyze light properties for chemical composition.

- Microscopes – Magnify small objects for detailed examination.

- Particle Counters – Measure the concentration of particles in air or liquids.

- Interferometers – Measure extremely small displacements and changes in wavelength.

Analog vs Digital Measurement Instruments

Measurement instruments can also be classified based on their output method.

Analog Instruments

Analog instruments display measurements using continuous scales, such as a needle pointing to a dial. They are often simple, durable, and require no power source. Examples include mechanical pressure gauges and analog voltmeters.

Digital Instruments

Digital instruments display measurements as numerical values on a screen. They generally offer better accuracy, higher resolution, and easier data recording. Examples include digital thermometers, digital calipers, and modern electronic scales.

Importance of Calibration

For measurement instruments to remain reliable, they must be periodically calibrated. Calibration is the process of comparing an instrument’s readings with a known standard to identify and correct deviations. Over time, factors such as wear, environmental conditions, and mechanical stress can cause measurement errors.

Calibration ensures:

- Consistent quality in manufacturing

- Compliance with industry standards

- Safety in engineering and medical applications

- Accuracy in scientific research

Many industries follow international calibration standards, such as ISO/IEC 17025.

Applications of Measurement Instruments

Measurement instruments are used across almost every sector of society.

Manufacturing and Engineering

Quality control in manufacturing relies heavily on precise measurements to ensure that products meet specifications. Tools like micrometers, CMMs, and laser scanners are used for dimensional inspection.

Construction and Architecture

Construction projects require accurate measurement of distances, angles, and levels. Laser levels, theodolites, and GPS-based survey equipment play vital roles in site layout and design implementation.

Healthcare and Medicine

Medical measurement instruments include blood pressure monitors, thermometers, and spirometers. Precision is critical to ensure correct diagnosis and treatment.

Scientific Research

In laboratories, instruments such as spectrophotometers, electron microscopes, and calorimeters are essential for data collection and analysis.

Environmental Monitoring

Weather stations use barometers, hygrometers, and anemometers to track environmental changes. Air and water quality monitoring instruments help protect ecosystems.

Transportation and Navigation

Speedometers, altimeters, and GPS devices rely on precise measurements to ensure safety and efficiency in transport systems.

Emerging Trends in Measurement Instruments

Technological advancements are shaping the future of measurement instruments.

Integration with IoT (Internet of Things)

Modern instruments can be connected to networks, allowing remote monitoring, automated data logging, and real-time analytics.

Miniaturization and Portability

Portable and handheld devices are becoming more powerful, enabling field measurements that previously required large equipment.

Non-Contact Measurement Technologies

Laser, ultrasonic, and infrared sensors are allowing measurements without physical contact, improving safety and convenience.

AI and Machine Learning in Measurement

Artificial intelligence is being integrated to interpret complex measurement data, identify patterns, and make predictive assessments.

Smart Calibration Systems

Automated calibration processes are reducing downtime and ensuring accuracy without human intervention.

Challenges in Using Measurement Instruments

Despite their usefulness, measurement instruments face certain challenges:

- Environmental Effects – Temperature, humidity, and vibration can affect readings.

- Human Error – Misreading scales or improper use can cause inaccurate results.

- Instrument Wear and Tear – Mechanical parts can degrade over time.

- Calibration Neglect – Skipping calibration can lead to accumulating errors.

Proper training, maintenance, and environmental control can minimize these issues.

The Future of Measurement Instruments

Looking ahead, measurement instruments will continue evolving to meet the demands of industries and research. Quantum measurement technologies promise unprecedented accuracy, potentially redefining standards for time, mass, and length. Autonomous measurement systems could integrate robotics and AI to perform inspections without human intervention.

The emphasis on sustainability will also influence instrument design, leading to energy-efficient, durable, and recyclable tools. Data integration will make instruments part of larger automated ecosystems, improving efficiency in manufacturing, healthcare, and environmental monitoring.

Conclusion

Measurement instruments are the backbone of modern civilization. They enable us to build infrastructure, develop technology, monitor the environment, and improve the quality of life. From a simple ruler to a complex atomic clock, these tools embody the human pursuit of precision and understanding.

The continued innovation in measurement instruments will lead to even greater accuracy, automation, and versatility. As industries demand higher standards and scientific research pushes the boundaries of knowledge, the importance of precise and reliable measurement tools will only grow.

In a world where accuracy drives progress, measurement instruments remain indispensable—quietly shaping the technology, safety, and efficiency of the systems we depend on every day.