In modern electronics, power management is critical. Devices such as laptops, smartphones, electric vehicles, and industrial machinery all require stable voltage regulation to function properly. This is where non-isolated DC-DC converters play a vital role. These converters provide efficient voltage step-up or step-down solutions without the need for galvanic isolation, making them smaller, more cost-effective, and widely applicable.

Unlike isolated converters, non-isolated designs connect the input and output grounds directly, which reduces size, complexity, and cost. Their versatility makes them the go-to choice in portable electronics, automotive power systems, and embedded applications. This article explores their working principles, types, design considerations, advantages, challenges, and future potential.

What Are Non-Isolated DC-DC Converters?

Non-isolated DC-DC converters are electronic circuits that convert one DC voltage level to another without electrical isolation between input and output. In other words, the input and output share a common ground. This makes them simpler, smaller, and often more efficient than isolated converters.

They are commonly used when:

- Safety isolation is not necessary.

- Space is limited.

- High efficiency and low cost are priorities.

Some of the most well-known non-isolated topologies include buck, boost, buck-boost, SEPIC, and Cuk converters.

How Do Non-Isolated DC-DC Converters Work?

These converters rely on switching regulators, which use semiconductor devices like MOSFETs or IGBTs to rapidly switch the input current on and off. The switching process, combined with inductors and capacitors, allows the circuit to either step down (buck) or step up (boost) the voltage as needed.

Key principles include:

- Energy storage in inductors.

- Pulse Width Modulation (PWM) to regulate duty cycles.

- Smoothing capacitors to reduce voltage ripple.

By controlling the switching frequency and duty cycle, designers achieve precise voltage regulation while maintaining efficiency.

Advantages of Non-Isolated DC-DC Converters

- High efficiency – Typically 85–95%.

- Compact size – No bulky transformers are needed.

- Cost-effective – Fewer components lower production costs.

- Fast response – Suitable for dynamic loads.

- Scalable – Works for small portable devices to large industrial systems.

Disadvantages and Limitations

While non-isolated converters are powerful, they come with limitations:

- No galvanic isolation – Unsafe for high-voltage applications where electrical isolation is mandatory.

- Limited input/output voltage ratios – Compared to isolated designs, the conversion range is narrower.

- Electromagnetic interference (EMI) – Switching regulators generate EMI that requires careful filtering.

- Thermal management – Higher current flow can cause heating issues.

Types of Non-Isolated DC-DC Converters

1. Buck Converter (Step-Down)

- Converts a higher DC voltage into a lower DC voltage.

- Example: Laptop adapters stepping down 19V to 5V for USB charging.

2. Boost Converter (Step-Up)

- Raises a lower DC voltage to a higher one.

- Example: Powering 12V LEDs from a 5V USB input.

3. Buck-Boost Converter

- Can step voltage up or down depending on duty cycle.

- Useful in battery systems where input voltage fluctuates.

4. SEPIC (Single-Ended Primary Inductor Converter)

- Provides positive output voltage with flexibility of buck and boost.

- Common in automotive electronics.

5. Cuk Converter

- Provides negative output voltage.

- Used in specialized industrial circuits.

Key Design Considerations

When designing non-isolated DC-DC converters, engineers must consider:

- Input and Output Voltage Range

- Ensure the topology can handle expected fluctuations.

- Ensure the topology can handle expected fluctuations.

- Load Requirements

- Match converter type with load demand (constant vs. dynamic loads).

- Match converter type with load demand (constant vs. dynamic loads).

- Switching Frequency

- Higher frequency reduces component size but increases EMI.

- Higher frequency reduces component size but increases EMI.

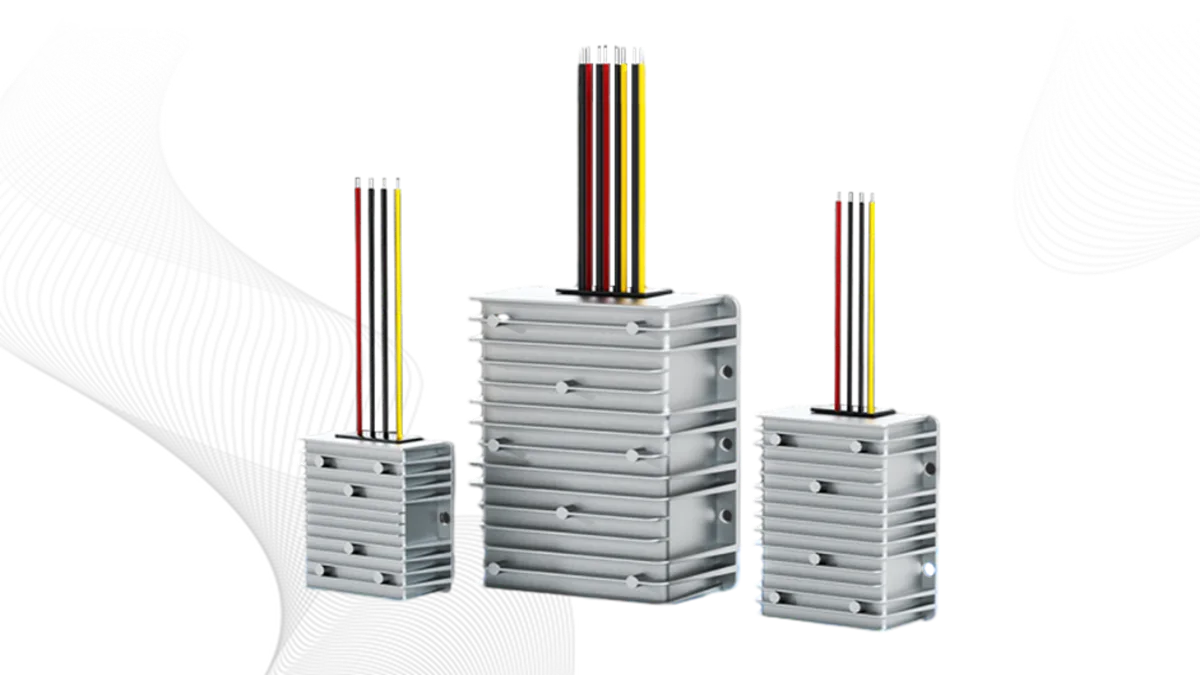

- Thermal Management

- Proper heat sinks and PCB layout to prevent overheating.

- Proper heat sinks and PCB layout to prevent overheating.

- Efficiency Optimization

- Balance switching losses with conduction losses.

Efficiency Challenges in Non-Isolated DC-DC Converters

Efficiency is one of the most important metrics in converter design. Some challenges include:

- Conduction losses in MOSFETs and diodes.

- Switching losses at high frequencies.

- Inductor core losses and parasitic resistance.

- Thermal dissipation, which can reduce lifespan of components.

Solutions often involve synchronous rectification, advanced MOSFETs, and digital control techniques.

Applications of Non-Isolated DC-DC Converters

Consumer Electronics

- Smartphones, laptops, and tablets rely on converters to regulate battery voltage.

Automotive Systems

- Electric vehicles (EVs) and hybrid vehicles use converters to manage 12V, 48V, and traction battery voltages.

Industrial Automation

- Powering sensors, controllers, and robotics where efficiency and compactness are essential.

Renewable Energy

- Solar inverters and battery storage systems integrate converters for voltage stability.

Communication Equipment

- Networking hardware and data centers use them for stable power delivery.

Safety Considerations

Although non-isolated designs are cost-efficient, safety is crucial. Engineers must:

- Use proper PCB isolation distances.

- Ensure input voltage is within safe limits.

- Add overvoltage, overcurrent, and thermal shutdown protections.

In high-voltage applications, isolated DC-DC converters are recommended instead.

Testing and Validation

Before deployment, converters undergo rigorous testing:

- Load testing for performance under varying conditions.

- Thermal analysis to prevent overheating.

- EMI testing for regulatory compliance.

- Reliability stress tests to ensure long-term durability.

Maintenance and Troubleshooting

When using a buck-boost converter, issues like unstable voltage or overheating may occur. Below are the troubleshooting steps:

- Check for overheating in inductors and switches.

- Inspect capacitors for swelling or leakage.

- Monitor EMI filters for wear.

- Use oscilloscopes to detect switching irregularities.

Future Trends in Non-Isolated DC-DC Converters

The future of these converters lies in:

- Wide Bandgap Semiconductors (GaN, SiC) for higher efficiency.

- Digital control systems for adaptive regulation.

- Integration into System-on-Chip (SoC) for compact electronics.

- AI-driven power management for predictive load adjustments.

As demand for efficient power electronics grows, non-isolated converters will become even more sophisticated.

Conclusion

Non-isolated DC-DC converters are essential in modern power electronics, offering high efficiency, compact design, and cost savings. They are widely used in consumer devices, automotive systems, renewable energy, and industrial automation. While they lack galvanic isolation, their advantages often outweigh this limitation in low to medium-voltage applications.

By understanding their types, design considerations, and efficiency challenges, engineers can optimize their use in real-world systems. As technology evolves, these converters will continue to shape the future of electronics and power management.