Silicone has become one of the most versatile materials in modern manufacturing. Whether you’re in the medical, automotive, electronics, or food industry, working with a trusted silicone products manufacturer ensures quality, safety, and performance. In this article, we explore the world of custom silicone products, their benefits, applications, and what to look for in a manufacturing partner.

What Are Silicone Products?

Silicone products are made from a synthetic polymer known as siloxane, composed of silicon, oxygen, carbon, and hydrogen. The material is known for its flexibility, durability, resistance to extreme temperatures, and non-reactive nature.

Benefits of Silicone Products

Choosing silicone over other materials offers several advantages:

1. Heat and Cold Resistance

Silicone can withstand temperatures from -60°C to +230°C, making it ideal for both freezing and heating applications.

2. Durability and Longevity

Silicone doesn’t degrade easily under UV light, water, or ozone, giving it a long life span even in harsh environments.

3. Non-Toxic and Food Safe

Medical-grade and food-grade silicones are safe for use in healthcare and culinary industries.

4. Flexibility and Elasticity

Silicone retains flexibility under pressure, making it perfect for sealing, molding, and cushioning applications.

Applications of Custom Silicone Products

Silicone products are used in various industries, including:

- Medical devices and implants

- Automotive gaskets and seals

- Consumer electronics and keypads

- Kitchenware and food storage

- Industrial components and insulators

Why Choose Custom Silicone Products?

While off-the-shelf silicone products serve standard needs, many industries require custom silicone solutions tailored to their specifications.

1. Precision and Performance

Custom silicone products are engineered to fit specific machines or applications, reducing inefficiencies and enhancing product performance.

2. Brand Identity and Innovation

Custom colors, designs, and textures allow brands to differentiate themselves in the market.

3. Compliance and Safety

Custom silicone manufacturing ensures your product meets industry regulations, including FDA, RoHS, and ISO standards.

Choosing the Right Silicone Products Manufacturer

Working with an experienced silicone products manufacturer is crucial for quality and reliability.

1. Expertise and Experience

Look for manufacturers with decades of experience and proven success in delivering both standard and custom silicone products.

2. Custom Capabilities

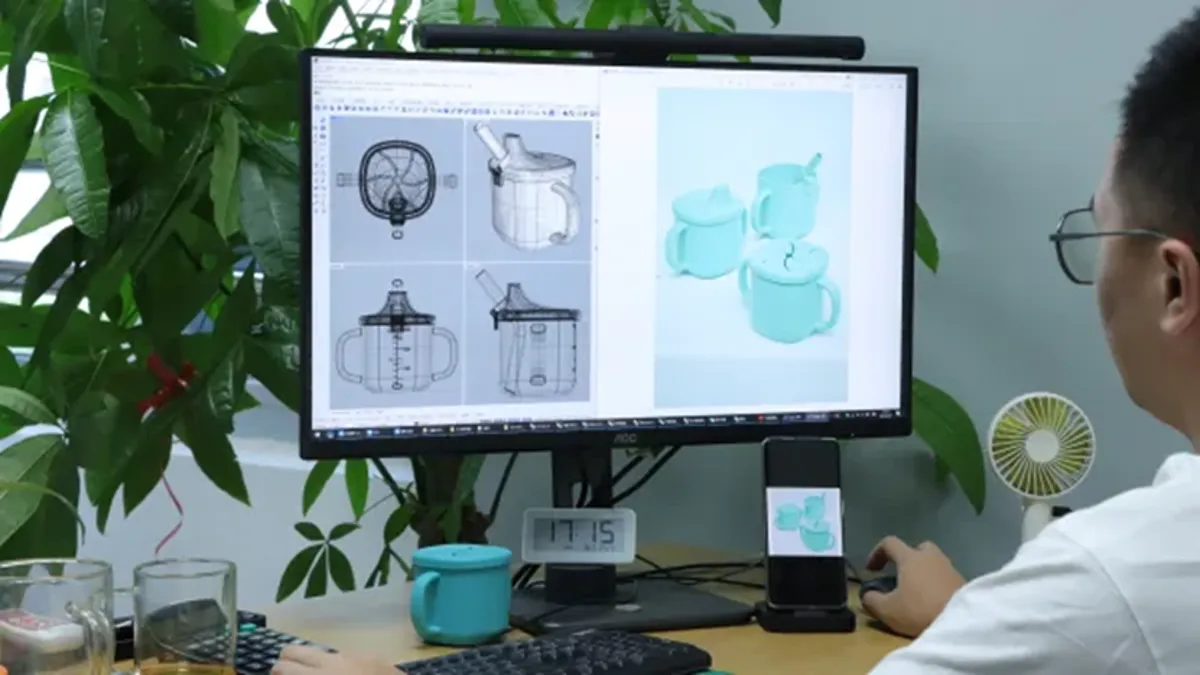

The ideal manufacturer should offer services like custom molding, prototyping, die-cutting, extrusion, and color matching.

3. Quality Assurance

Ensure the manufacturer follows strict quality control protocols, including ISO 9001:2015 certification or equivalent.

4. Material Selection

Manufacturers should offer a range of silicone materials, including:

- Medical-grade silicone

- Food-grade silicone

- Flame-retardant silicone

- High-consistency rubber (HCR)

- Liquid silicone rubber (LSR)

Custom Silicone Molding Techniques

There are several techniques used in custom silicone manufacturing:

1. Compression Molding

Ideal for producing high-strength, large-volume silicone parts. Cost-effective and widely used in automotive and industrial sectors.

2. Injection Molding

Best for complex, high-precision parts. Used in medical, electronics, and consumer product manufacturing.

3. Liquid Injection Molding (LIM)

Utilizes liquid silicone rubber (LSR) for high-volume, precision parts. Suitable for intricate medical or electrical components.

Industries That Rely on Custom Silicone Manufacturing

Medical and Healthcare

- Surgical tools

- Seals and valves

- Prosthetics and implants

Automotive and Transportation

- Engine gaskets

- Hoses and tubing

- Vibration dampeners

Consumer Products

- Baby products

- Kitchen utensils

- Phone accessories

Electronics

- Insulators

- Keypads

- Connectors

Sustainable and Eco-Friendly Silicone Options

Today, many silicone manufacturers are adopting eco-conscious practices. These include:

- Recyclable silicone products

- Non-toxic, BPA-free materials

- Energy-efficient production methods

Choosing an environmentally responsible manufacturer helps reduce your carbon footprint and aligns with sustainable business practices.

Future Trends in Silicone Manufacturing

The future of silicone manufacturing is promising, driven by innovation and sustainability:

- Smart silicone products (e.g., conductive or sensor-integrated)

- 3D printing with silicone materials

- Biodegradable silicone blends

- Automated production and AI quality checks

Conclusion: Find a Silicone Manufacturer You Can Trust

When it comes to custom silicone solutions, choosing the right silicone products manufacturer is a critical decision. Whether you’re creating medical devices, kitchen gadgets, or automotive parts, your manufacturer should deliver reliability, compliance, and innovation.

Start your custom silicone project today with a trusted partner that meets your needs from concept to production.