Steel machining is a subtractive manufacturing process that removes material from a steel workpiece using machine tools and sharp cutting edges to produce a desired shape or part. Steel machining process starts with raw steel stock, like bars or billets, depending on the machine: lathes or mills. Carbide-cutting tools or HSS tools cut excess material through a precise and controlled motion.

Steel CNC machining involves cutting parameters including cutting speed (50 – 200 ft/min), feed rates of (0.002 – 0.020 inch/tooth), and up to 0.2 inch depth of cut. It is necessary to use coolants in steel machining to prevent heat buildup, wall distortion, and improve accuracy.

Steel Machining Operations

The motion of the tool and the workpiece categorizes steel machining operations. Some of these steel machining operations include turning for cylindrical parts, milling for rectangular parts, drilling for holes, and grinding for surface finishing.

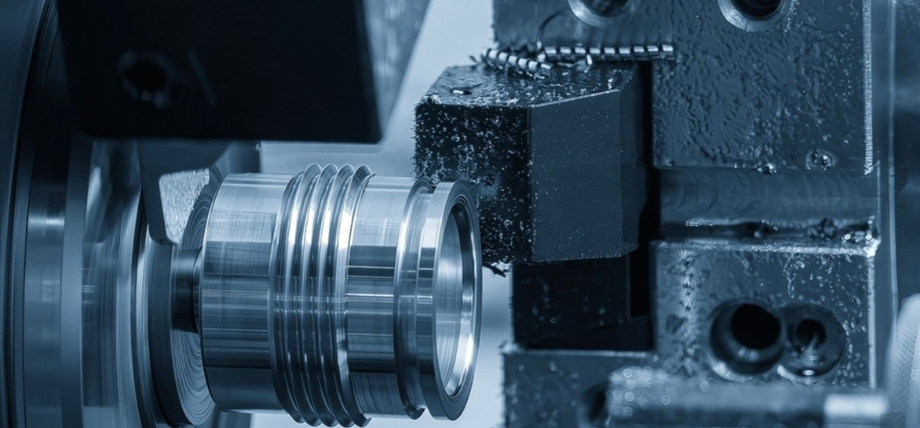

Turning Steel

Turning involves rotating the steel workpiece inside the chuck of a lathe machine, where a single-point cutting tool comes into contact with the workpiece, removing material to form tapers, holes, grooves, or cuts. For 1045 carbon steel, the typical parameters are 600 – 800 ft/min and up to 0.1 inches depth of cut with carbide inserts coated with TiAlN for heat resistance.

Variations of turning machining for steel include facing, grooving, and contour turning for non-cylindrical profiles.

Milling

Milling uses a multi-toothed rotary cutter that advances into a stationary workpiece clamped in a vice on a milling machine table. Milling steel produces flat surfaces, slots, and complex contours. Peripheral (side) milling, where the cutter’s teeth engage the side, and face milling, where the cutter face engages the workpiece for a broader surface. For alloy steel the recommended speeds are around 150 – 300 SFM and feeds of around 0.003 – 0.012 inch per tooth. Different grades require different speeds and feeds for milling stainless steel parts.

End milling for steel uses small diameter tools for pockets and profiles, while slab milling handles larger faces. High-speed steel (HSS) or indexable carbide tools with a variable helix angle are used for enhanced chip evacuation.

Drilling

Drilling in a steel part

Drilling creates cylindrical holes in steel by rotating a multi-flute twisting tool that moves axially up or down, cutting through material. For most austenitic steels, the best settings use a 70 – 120 meters per minute speed and between 0.1 – 0.25 mm/rev feed.

Grinding

Grinding is a surface finishing process for steel that uses an abrasive wheel that removes a tiny amount of material and produces microscopic chips. It is used to achieve tolerances of +/- 0.0005 inches and surface finishes below 16 microinches Ra. Grinding steel is generally done using an abrasive grinding wheel or pads made from aluminum oxide and soluble oils to flush out the tiny chips and keep the surface finishing process cool.

Tapping

Threading a stainless steel part

Tapping is a method to form internal threads by rotating a tapered or straight-flute tap into a pre-drilled hole where material is cut to match the thread profile. Spiral point taps eject chips forward and are suitable for blind holes.

Types of Steels for Machining

Alloy Steel Machining

Alloy steels contain a range of elements like chromium, nickel, and molybdenum to improve tensile strength and wear resistance, as well as lower thermal conductivity. Alloy steels are difficult to machine due to heat buildup and higher tool wear rates compared to carbon steels. The machinability for alloy steel is between 40% to 60% and requires a rigid fixture due to its brittleness.

Carbon Steel Machining

Carbon steel nuts and fasteners

Carbon steel has a higher carbon content compared to other steels. The higher carbon grades of steel are more difficult to machine. Low-carbon grades are easier to machine and have better chip control. Low carbon grades can be machined at 120 – 180 SFM, and high carbon steel grades require slower machining rates and coated tools to manage abrasive carbides.

Stainless Steel Machining

Stainless steel is the most common type of steel for machining and has a great mix of strength and corrosion-resistant properties. Ferritic grades have a machinability rating of around 80% or more, depending on the carbon percentage in stainless steel. Stainless steels are machined using high-speed steels and carbide steels. Common stainless steel grades like 304 and 316 produce gummy chips and undergo work hardening, making stainless steel machining difficult.

Tool Steel Machining

Tool steel is a subclass of steel made from alloying different metals and comes in different hardening types like high-speed types (M2) or oil hardening (O1). Tool steels are machined using carbide tools and most are machined through the EDM process to produce precise cuts and precision up to +/- 0.01 mm for molds and casings.

Free-Machining Steels

Free machining steels have sulfur, lead, or calcium promote chip breaking and improve machinability. The addition of sulfur or calcium can reduce tool wear and increase machining efficiency, but the use of lead is generally avoided due to environmental concerns. Common free machining steel grades include 1215 and 1214 (led), ideal for high-volume parts like fasteners.

Benefits of using free-machining steel include faster cycle times and better Ra finishes.

CNC Steel Fabrication Tips

- Simulate paths in CAD/CAM with FEA analysis for stresses to ensure the design does not exceed allowable stress limits and maintains structural integrity.

- Deburr post-process to 0.010-0.015 in. edges

- Match the tool rake to the steel hardness

- Check spindle runout to <0.0002 inches using dial indicators

- Program CNC machines and G-code to feeds and speeds that match the steel machinability and hardness.

- Vacuum tables for rigid fixturing to limit vibration

Conclusion

Steel machining is a key process in the suite of precision machining materials with its wide applications across different industries and hundreds of grades. Steel machining requires different operations like turning, milling, EDM, and grinding to produce precise parts. From carbon to free-machining variants, steel fabricators achieve superior mechanical properties by adapting the machining process.