Pneumatic valves may be small, but they punch way above their weight in industrial automation. They steer compressed air to the very tools and machines that keep a factory humming. When production schedules tighten, the pressure to source quality valves on time can really mount. That makes picking a dependable pneumatic valve supplier a mission-critical task, not just an afterthought.

A supplier that stocks innovative automation products for factories can shave hours off your project timetable and save money in the long haul. Engineers, project leads, and procurement teams alike notice the difference when uptime jumps and headaches shrink. This post lays out the key points to double-check the next time you vet a valve source.

Understanding the Role of Pneumatic Valves in Automation

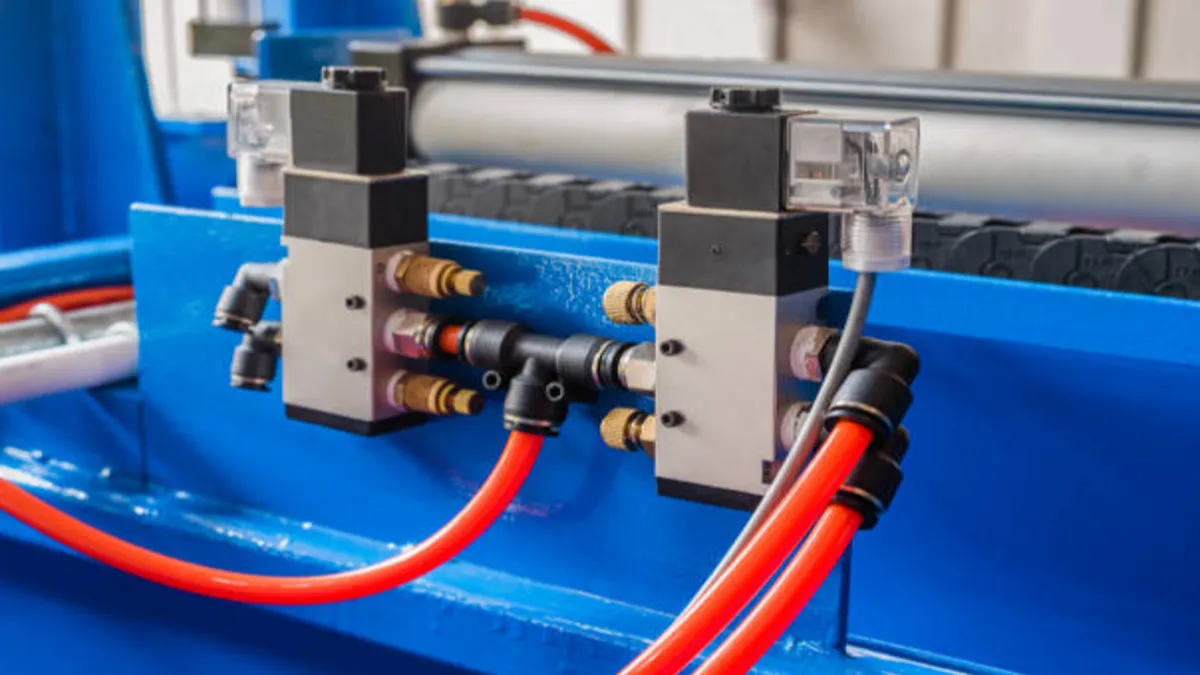

Think of a pneumatic valve as the traffic cop for compressed air. It points the airflow where it needs to go, whether that’s a cylinder, a gripper, or a spray gun. Control over direction, pressure, and volume is baked right into the design. You’ll find these valves parked in assembly lines, food-pack stations, warehouse sorters, and pretty much anywhere that air power gets things moving.

Valves are a gadget that shows up in all kinds of shapes, so you won-t just see one style on the shelf.

- A 2-way or 3-way part flips the flow and either opens or closes things quickly.

- A chunky 5-way valve keeps double-acting cylinders moving back and forth without a hitch.

- Proportional valves act like a dimmer switch, letting you fine-tune how much air or fluid gets through.

- Slap an electric coil on it and you’ve got a solenoid valve that answers to buttons, sensors, or PCs.

Why Picking the Right Pneumatic Valve Supplier Matters

Once you decide on the valve, the next chapter is searching for the company that delivers it. Shoddy shipping plagues well-planned projects, so a solid supplier turns into a quiet ally.

Good partners don-t just drop parts on your dock; they know the headaches that come with running a line. Their engineers answer urgent questions, and their paperwork matches the latest industry checks.

Flip the script, and cheap fittings chain-react into bigger costs. Bad suppliers leak quality, miss deadlines, and leave you filling out your own certificates while a system sits idle.

A proven vendor opens the door to modern gadgets that automate a factory from corner to corner. More reliable valves mean more reliable machines, and sooner than later, those small wins stack into a plant that just works.

Top Things to Check When Choosing a Pneumatic Valve Supplier

Picking the right supplier is a big deal for any factory. Keep the list below handy so you don-t overlook anything important.

Product Range and Fresh Ideas

Start by scanning the product catalog. You’re after a full mix of valve sizes, actuation styles, and specialty versions that fit your machines.

Next, look for cool new features. Valves packed with sensors, low power use, or click-together parts show the seller is chasing tomorrow’s tech. Having that edge on innovation can save your plant money down the road.

Engineering Help When You Need it

Valves rarely install themselves, especially in a custom layout. A good supplier backs the sale with solid engineering support.

Ask if they provide ready-to-use CAD drawings, tweaking tips for your PLC, and quick fixes when things stall. Fast answers cut the time your crew spends hunting bugs.

Quality Proofs That Matter

Words about quality mean little without hard proof. Request the usual certificates-ISO, CE, RoHS-plus the test sheets that trace each part through the foundry.

Detailed reports showing performance at peak pressure and temperature let you sleep at night. The right paperwork turns a hunch about reliability into a guarantee.

Lead Time and Inventory Management

Speed is everything on the factory floor. A solid pneumatic valve supplier should be able to:

- Keep popular parts in stock so you don’t hit dead air.

- Ship overnight when a machine suddenly gasps for breath.

- Flex its schedule for projects that stretch over months or even years.

Suppliers with a network of warehouses or real-time inventory dashboards usually close the agility gap.

Reputation and Industry Experience

Years in the game often stack up as a badge of trust. Before you sign, find out:

- How long has the company been pushing pneumatic gear?

- Which markets-packaging, food processing, semiconductors-does it call home?

- Can it point you to unedited customer stories or hard-case examples?

A supplier steeped in your field is more likely to dodge rookie slip-ups with permits, specs, and oddball rule sets.

Local vs. Global Pneumatic Valve Suppliers

At some point in your project, you’ll probably have to pick between a neighborhood distributor and a worldwide manufacturer. Each choice carries its own set of trade-offs.

Local Suppliers

- Faster Deliveries: Orders can land on your loading dock before you finish your coffee.

- Easy Communication: Face-to-face chats clear up questions in minutes.

- Regulatory Know-How: Your supplier already understands the codes and rules on the books.

Global Suppliers

- Wider Catalog: One stop may land everything from basic ball valves to cutting-edge adaptive tech.

- Emerging Innovations: Large firms often pilot new products before anyone else notices.

- Multi-Site Scalability: One contract can cover factories in three countries without extra legwork.

Big-volume or multi-country projects often tip the scales toward a global source. Still, several engineers discover that pairing a worldwide brand with a local rep delivers speed, service, and selection in one neat package.

Questions to Ask Before Finalizing a Supplier

Before you fire off that first purchase order, pause and run through a quick quiz:

- How many days do you usually need to ship a batch of pneumatic valves?

- Can you share any compliance certificates or technical test papers?

- What kind of help do you offer when we try to wire the valves into our automation setup?

- Do your mounting holes and electrical plugs align with the industry standard?

- If something is wrong, what process do you have for returns or troubleshooting?

Asking these things gives you a peek at the supplier’s responsiveness and honesty. If you can, swing by the shop floor or watch a live demo-you’ll learn a lot in just an hour.

Real-World Impact of Choosing the Right Supplier

Picture a car-parts plant that swaps its old pneumatic-valve vendor for one selling next-gen models with smart sensors. A year later the numbers look like this:

- Energy bills are down 15 percent.

- Unplanned repairs are 20 percent fewer.

- Technicians fix problems faster because diagnostics light up right away.

- Overall output through the assembly line is up. Those statistics show that picking the right supplier can actually ripple through the entire factory and save real cash.

Conclusion

Pneumatic valves really are the hidden pulse of most auto-mated plants. Pick the right supplier, and machines glide along; settle for a half-hearted choice, and delays pile up like old freight cars.

Start your short-list with names that roll out a full suite of smart factory gear, ship on time, and stand behind the kit with solid tech help. When the factory floor keeps shifting under your feet, a supplier that bets on fresh ideas lets your lines stay quick, flexible, and ready for tomorrow.