In the fields of engineering, construction, and manufacturing, material selection is a balancing act. You need materials that are strong, durable, and cost-effective, but also workable and adaptable to various needs. This is where 6061 aluminum and its counterpart, 6060 aluminum, truly excel. As standout members of the 6000 series aluminum alloys, they offer an exceptional blend of properties that make them two of the most versatile and widely used metals on the market.

This article will dive into the characteristics that make 6061 and 6060 aluminum so popular. We will explore their excellent strength, formability, and corrosion resistance, compare their specific attributes, and highlight their key applications across multiple industries. Understanding the benefits of these alloys will help you make a smart, effective choice for your next project.

An Overview of the 6000 Series: The All-Round Performers

The 6000 series of aluminum alloys use magnesium and silicon as their primary alloying elements. This combination allows them to be heat-treated, which significantly improves their strength while maintaining good formability and weldability. Unlike the ultra-high-strength 7000 series or the specialized 2000 series, the 6000 series is celebrated for its balanced, all-around performance.

Key features of this series include:

- Excellent Corrosion Resistance: They hold up well against atmospheric and environmental corrosion.

- Good Formability and Weldability: They are easy to extrude, form, and weld, making them ideal for complex shapes.

- Moderate to High Strength: After heat treatment, they offer substantial strength suitable for many structural applications.

6061 Aluminum: The Structural Workhorse

When engineers and designers need a reliable, do-it-all material, they often turn to 6061 aluminum. It is arguably the most common aluminum alloy for general-purpose structural use, prized for its excellent mechanical properties and tremendous versatility.

Key Properties of 6061 Aluminum

In its popular T6 temper, 6061 aluminum offers good strength, making it suitable for a wide range of load-bearing applications. It is easily welded and machined, and its exceptional corrosion resistance means it can be used in various environments without significant degradation. This combination of workability and durability makes it a highly economical choice for many projects.

It’s this balance that makes it so valuable. You get a material that is strong enough for structural frames but can also be easily fabricated into intricate parts. According to a 2024 industry report, the construction and automotive sectors together account for nearly 50% of all 6061 aluminum consumption, a testament to its wide-ranging utility [Source: Modern Metals Market Analysis].

Where 6061 Aluminum Is Used

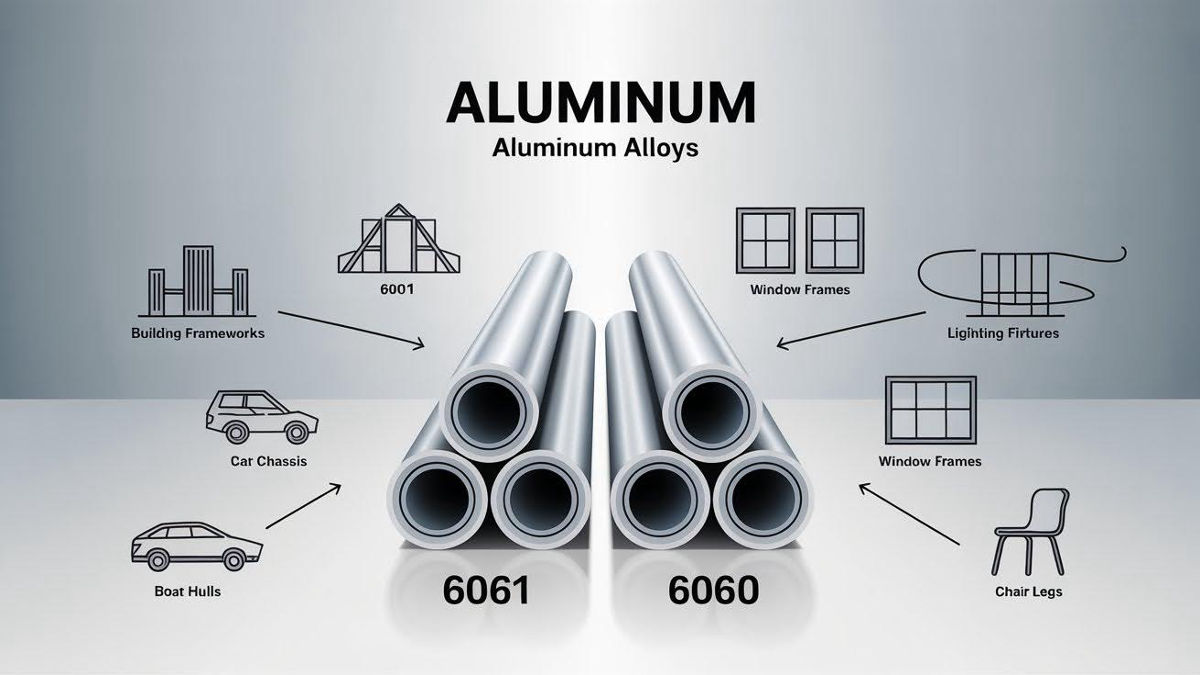

You can find 6061 aluminum in an incredibly diverse array of products, including:

- Architectural and Structural Applications: Window frames, door frames, and building facades.

- Automotive and Transportation: Chassis components, vehicle frames, and body panels.

- Marine Applications: Boat hulls and other components that require a corrosion-resistant aluminum.

- Consumer Products: Bicycle frames, scuba tanks, and fishing reels.

6060 Aluminum: The Extrusion Specialist

While closely related to 6061, 6060 aluminum has a slightly different chemical composition that gives it a unique advantage: superior formability. It is one of the best alloys for producing complex extruded shapes, making it a favorite for architectural and decorative applications.

Unique Advantages of 6060 Aluminum

The primary benefit of 6060 aluminum is its excellent extrudability. It flows more easily through extrusion dies, allowing for the creation of intricate, thin-walled profiles with a high-quality surface finish. This makes it ideal for applications where visual appearance is important. It also responds very well to anodizing, which can be used to add color and further enhance its already good corrosion resistance. While it has lower strength than 6061, it is more than sufficient for many non-structural or lightly loaded applications. (External Link: The Aluminum Extruders Council)

Common Applications for 6060 Aluminum

The superb formability and finish of 6060 aluminum make it the go-to choice for applications where aesthetics and complex shapes are key. These include:

- Architectural Systems: Custom window and door systems, curtain walls, and interior fittings.

- Lighting and Furniture: Housings for light fixtures, furniture frames, and decorative trim.

- Automotive Trim: Used for decorative trim and other non-structural parts.

- Heat Sinks: Its ability to be formed into complex shapes makes it great for creating custom heat sinks for electronics.

6061 vs. 6060: Choosing the Right Alloy for Your Needs

The choice between 6061 aluminum and 6060 aluminum depends on whether your priority is strength or formability.

A Head-to-Head Comparison

Here’s a quick guide to help you decide:

- For Structural Applications: If your project requires good load-bearing capabilities, 6061 aluminum is the clear winner. Its higher strength makes it the standard for frames, supports, and other structural components.

- For Complex Shapes and Finishes: If you are designing a product with an intricate profile or one where a high-quality surface finish is critical, 6060 aluminum is the superior choice. Its excellent extrudability is unmatched.

- Weldability and Machinability: Both alloys offer good weldability and machinability, but 6061 aluminum is generally considered slightly better for machining operations.

By aligning the alloy’s strengths with your project’s primary requirements, you can optimize for both performance and cost. Consulting with a supplier who understands the nuances of these materials can provide invaluable guidance. (Internal Link: Linsy Aluminum 6000 Series Products)

Conclusion

Both 6061 aluminum and 6060 aluminum are outstanding materials that offer a fantastic combination of properties for a wide range of applications. As versatile members of the 6000 series aluminum alloys, they provide the perfect solution for countless engineering and design challenges. 6061 serves as the dependable structural workhorse, while 6060 provides unmatched formability for complex and aesthetically demanding projects.

Harnessing the full potential of these alloys starts with sourcing high-quality material from a reliable supplier. A knowledgeable partner can help you navigate the options and provide certified materials that meet your exact specifications.

Ready to find the perfect aluminum for your versatile application? Explore the comprehensive selection of 6000 series alloys at Linsy Aluminum and request a quote today.